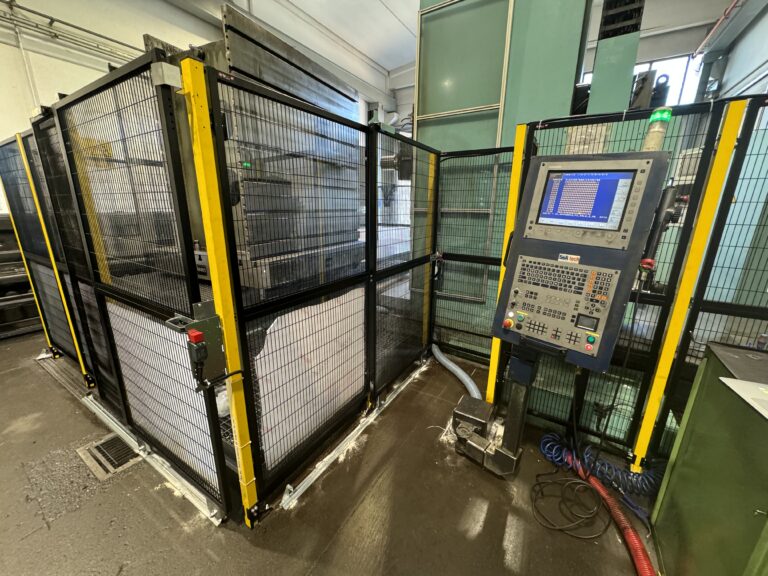

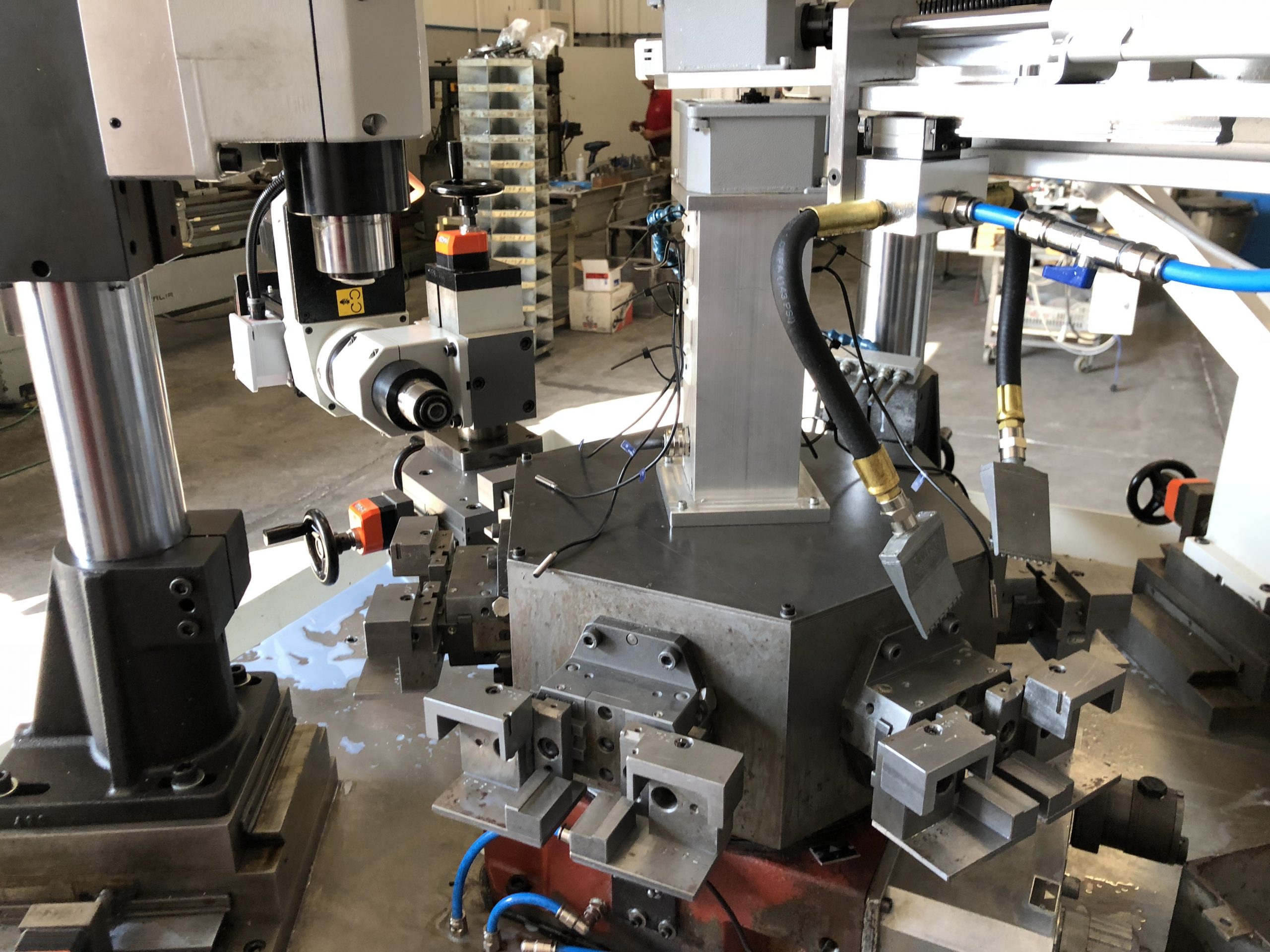

Robot-assisted work cells

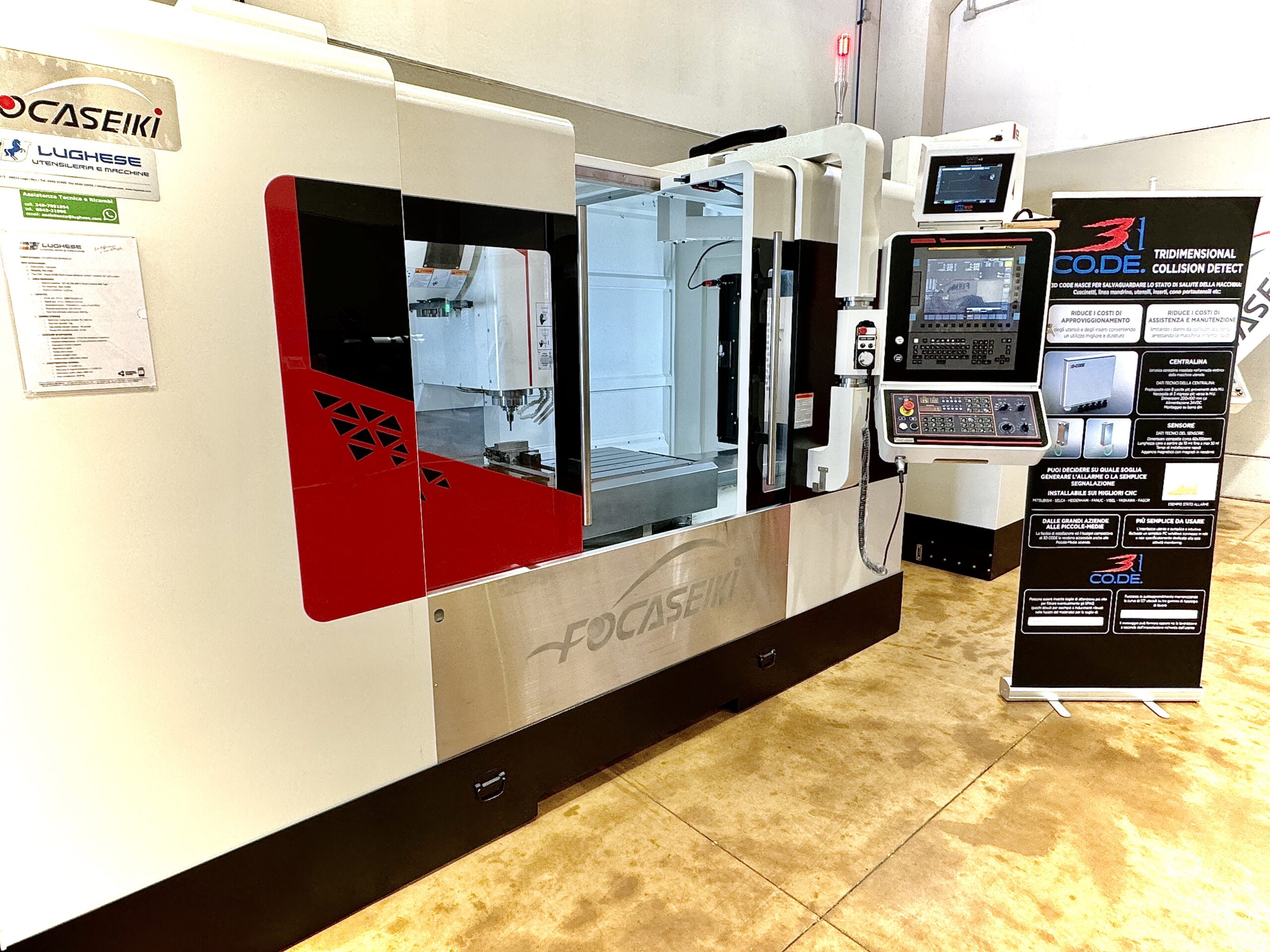

Machine Compliance

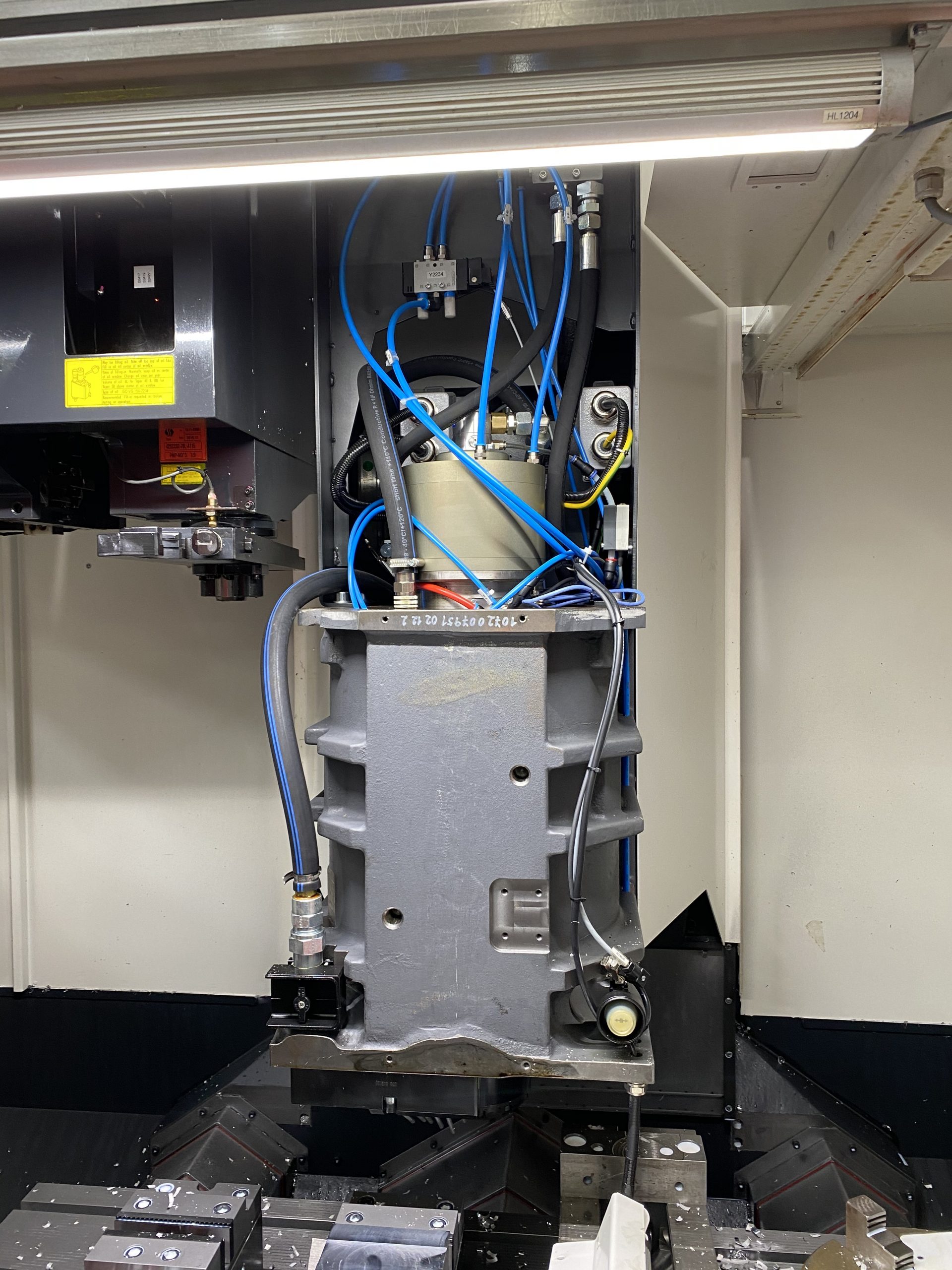

Collision Detection Sensor

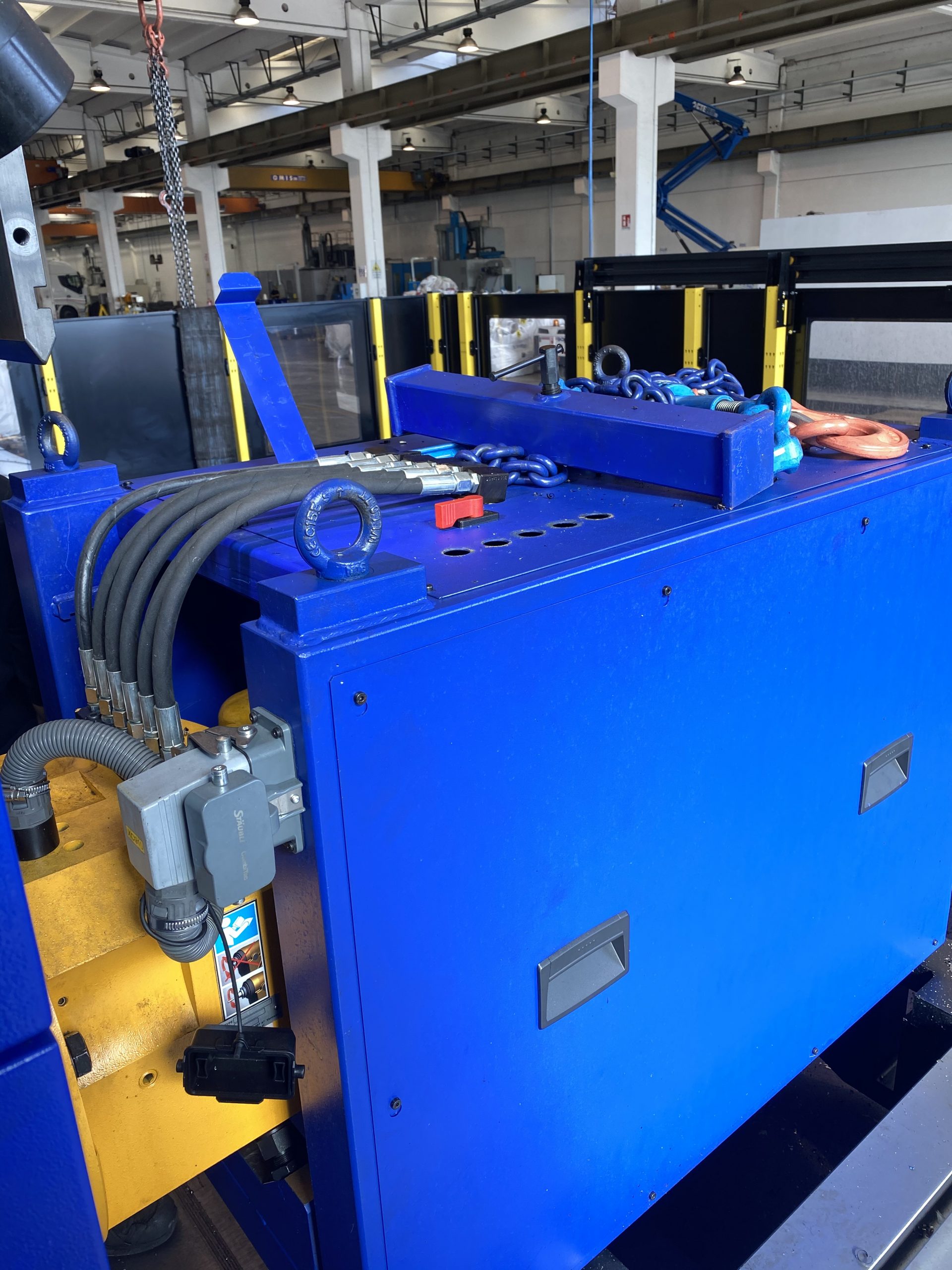

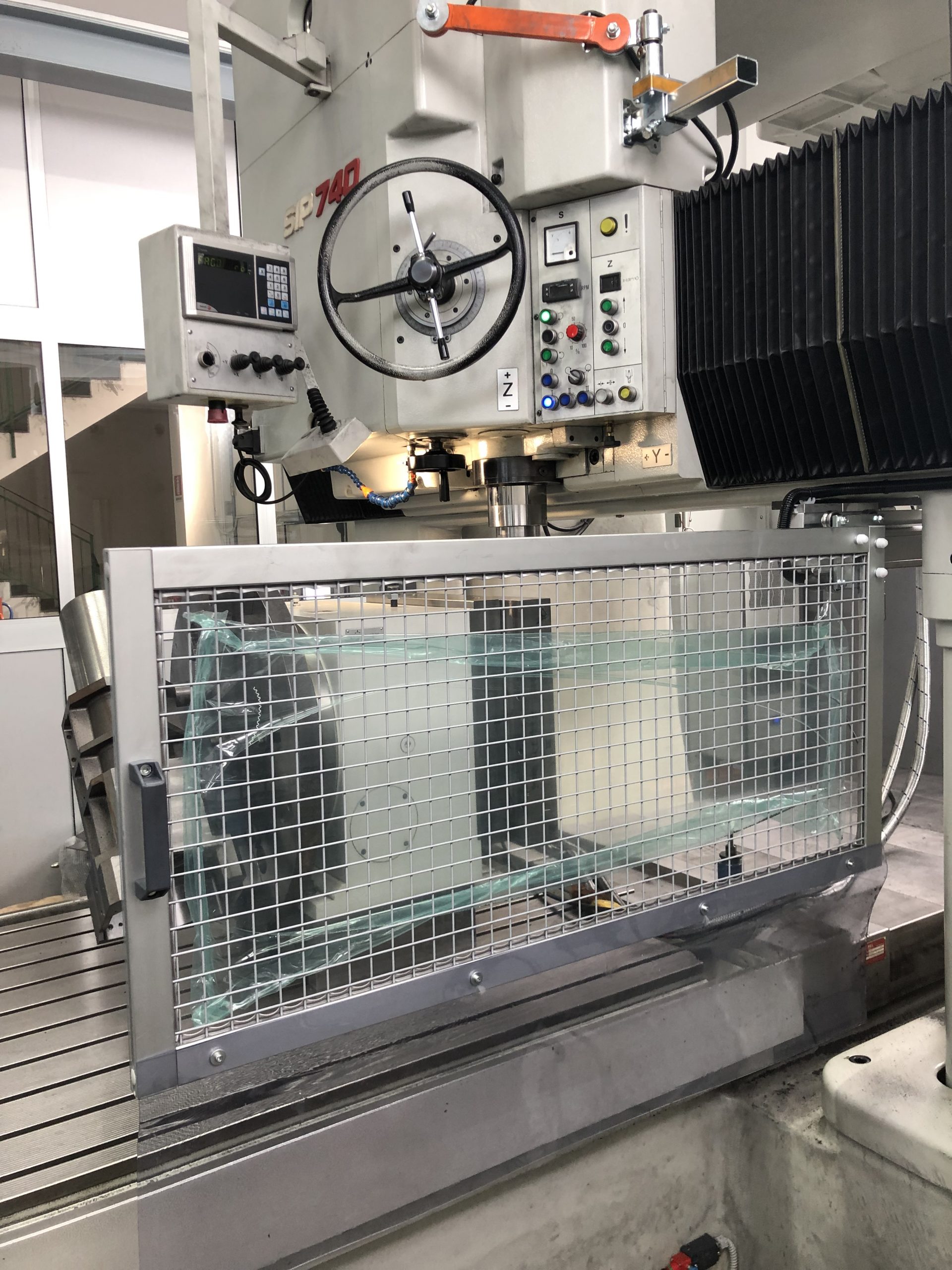

Assembly and Installation of Tables

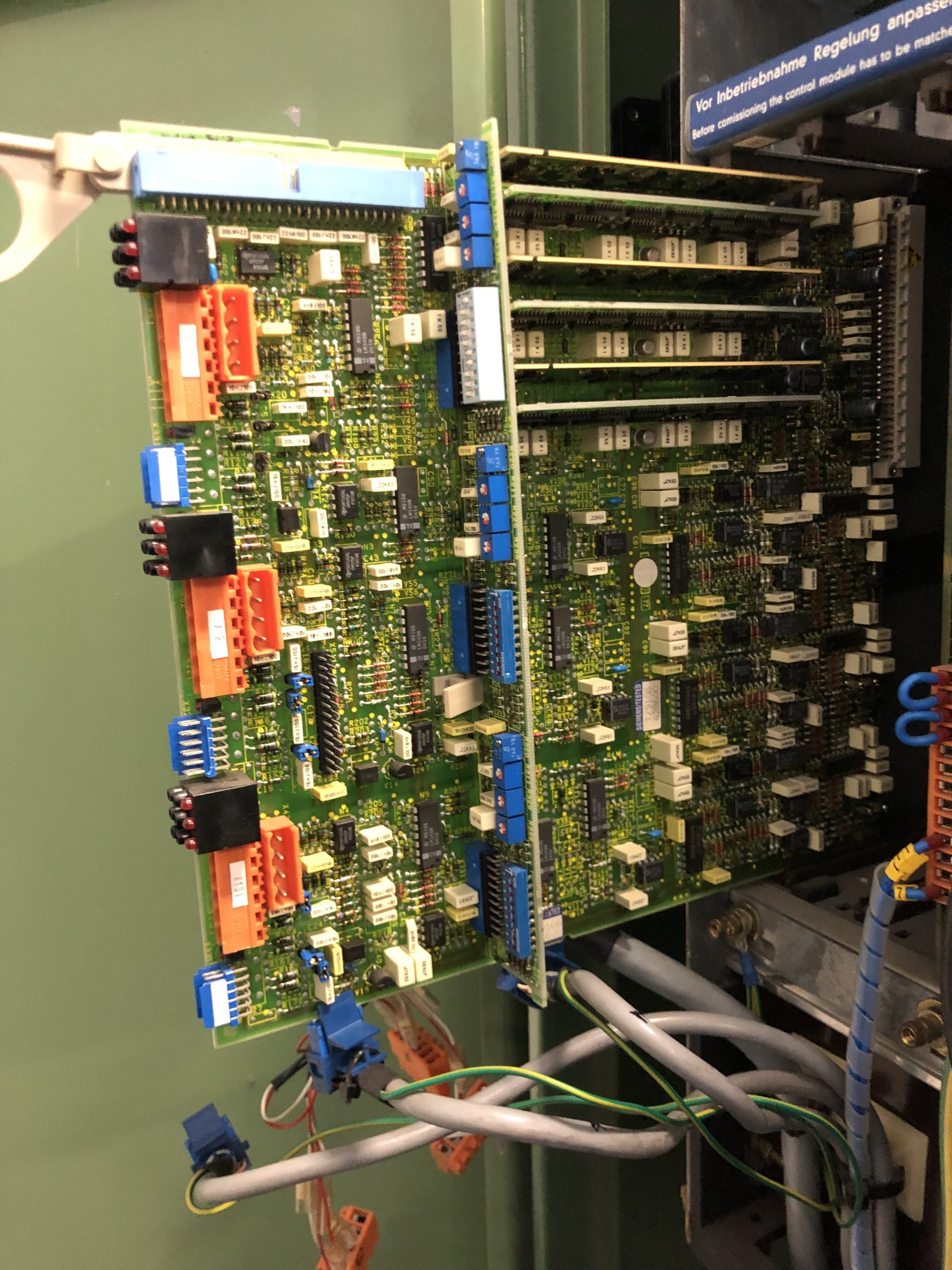

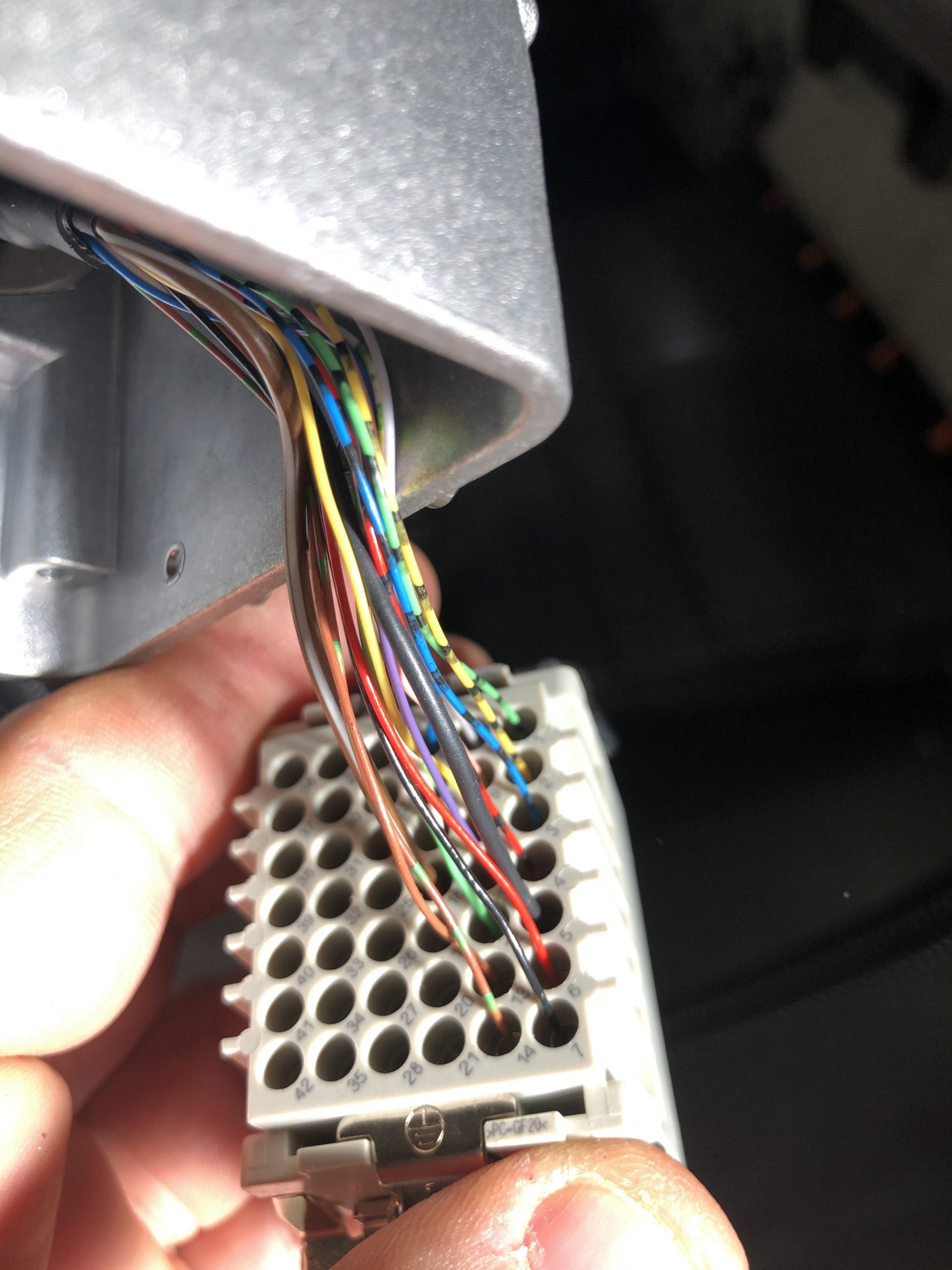

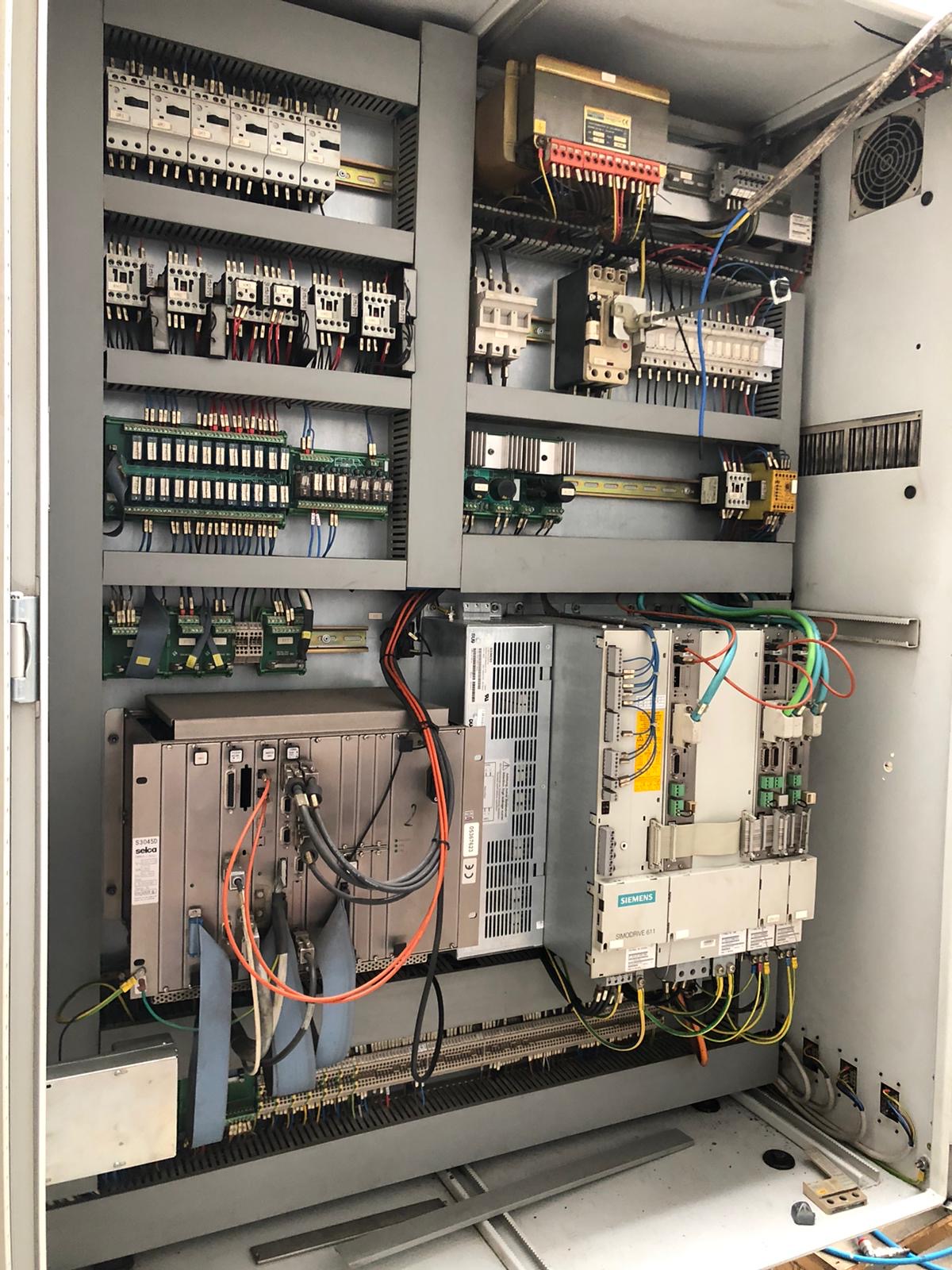

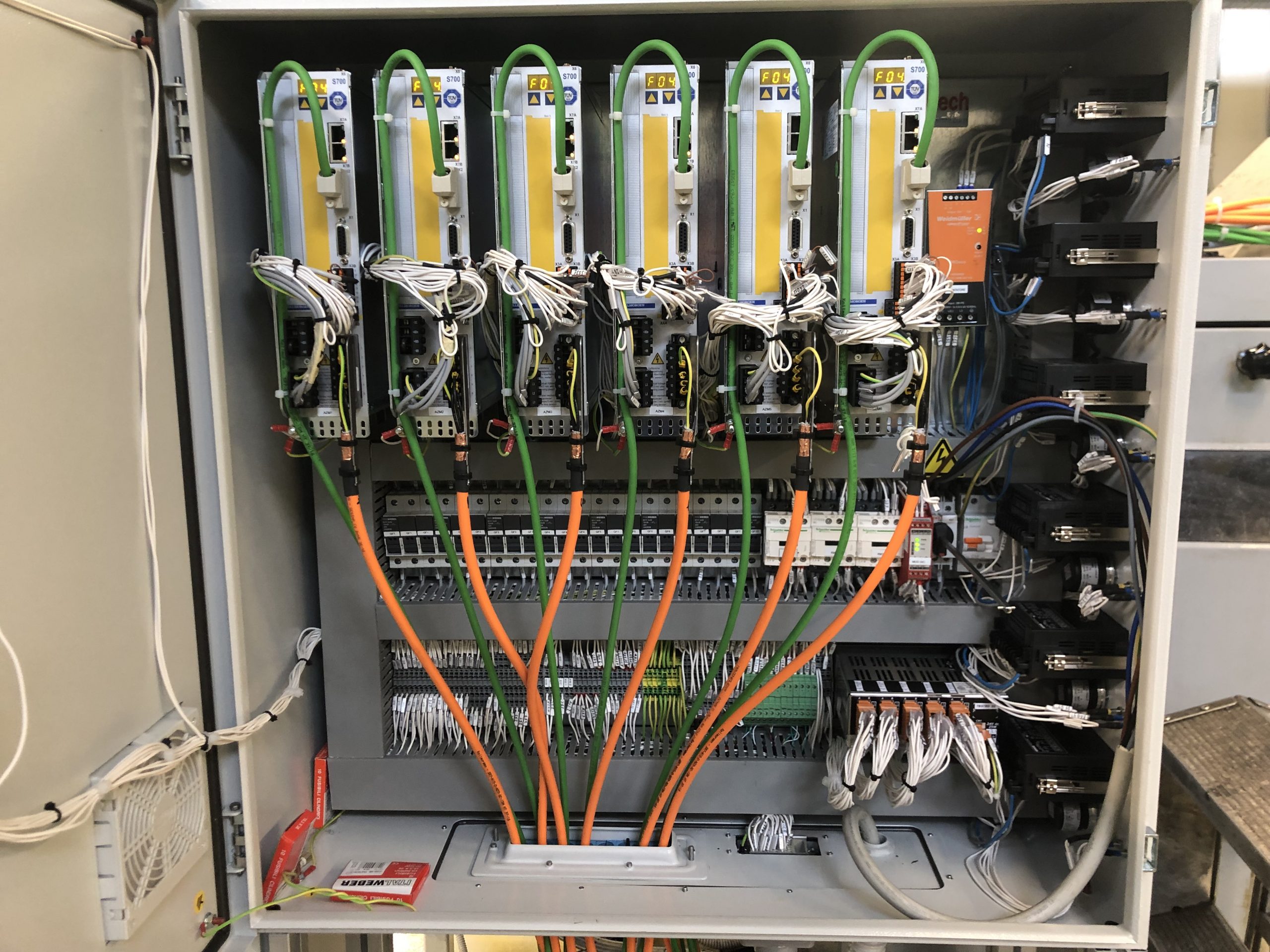

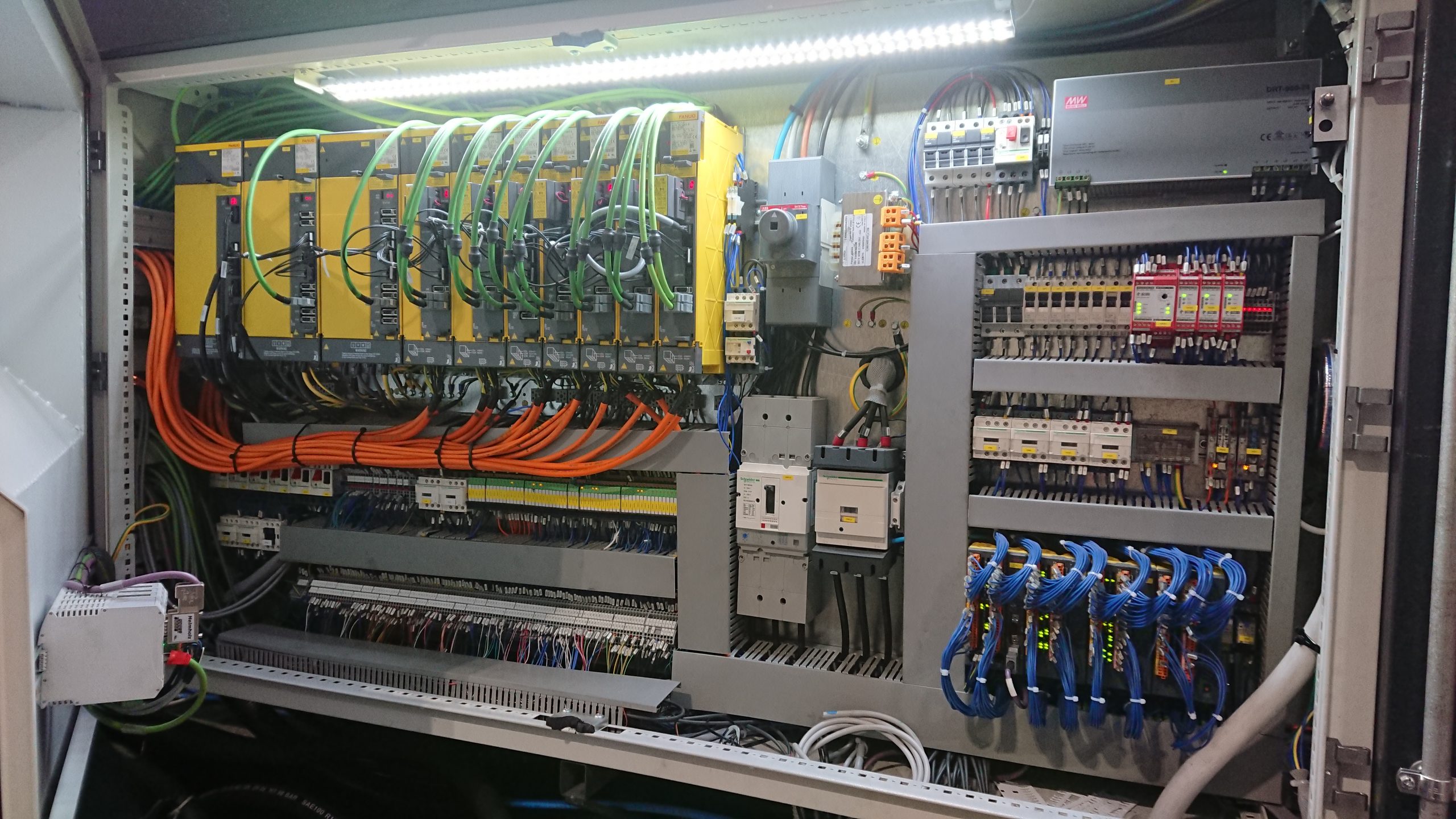

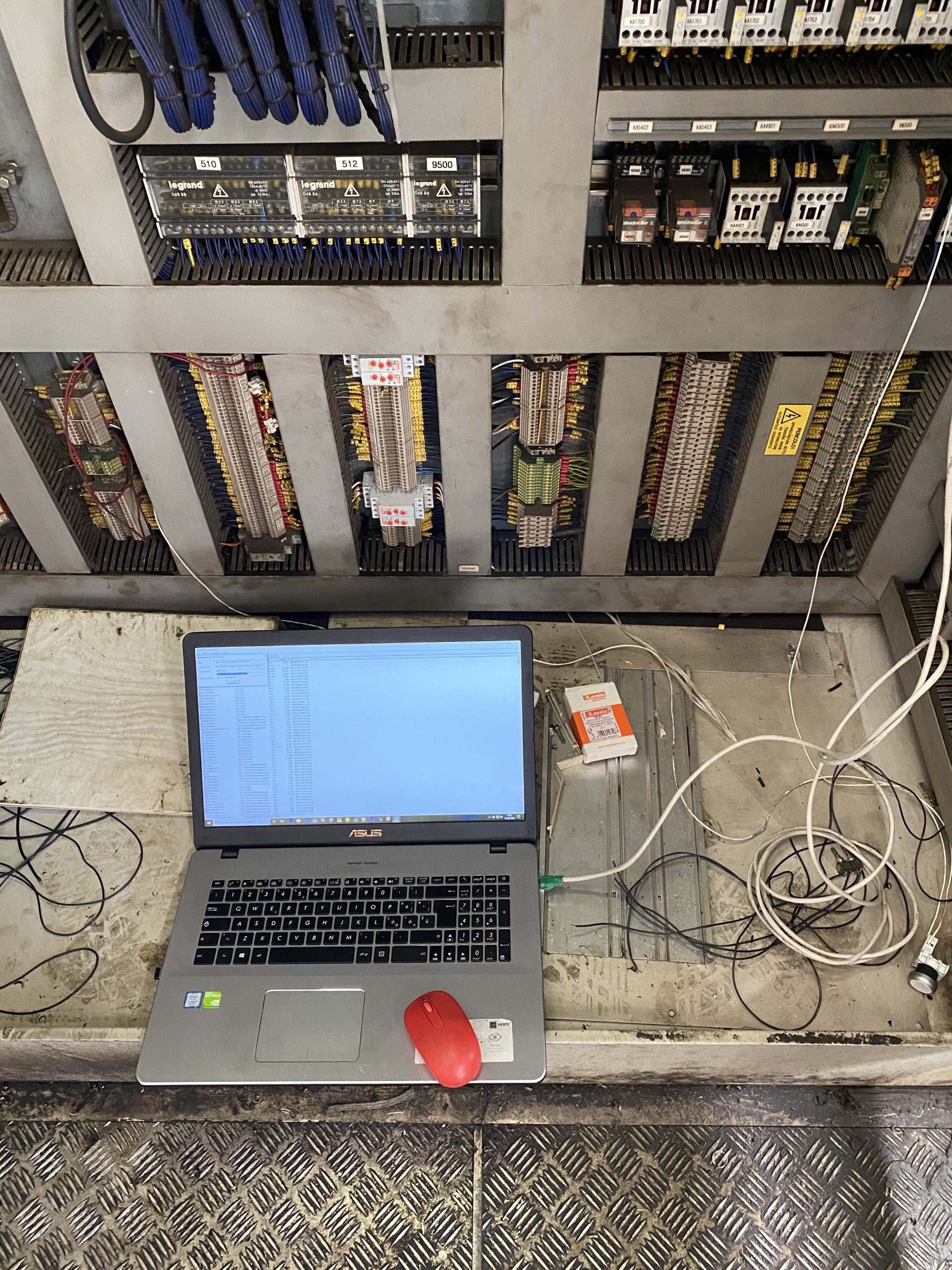

Electrical and Electronic Assistance

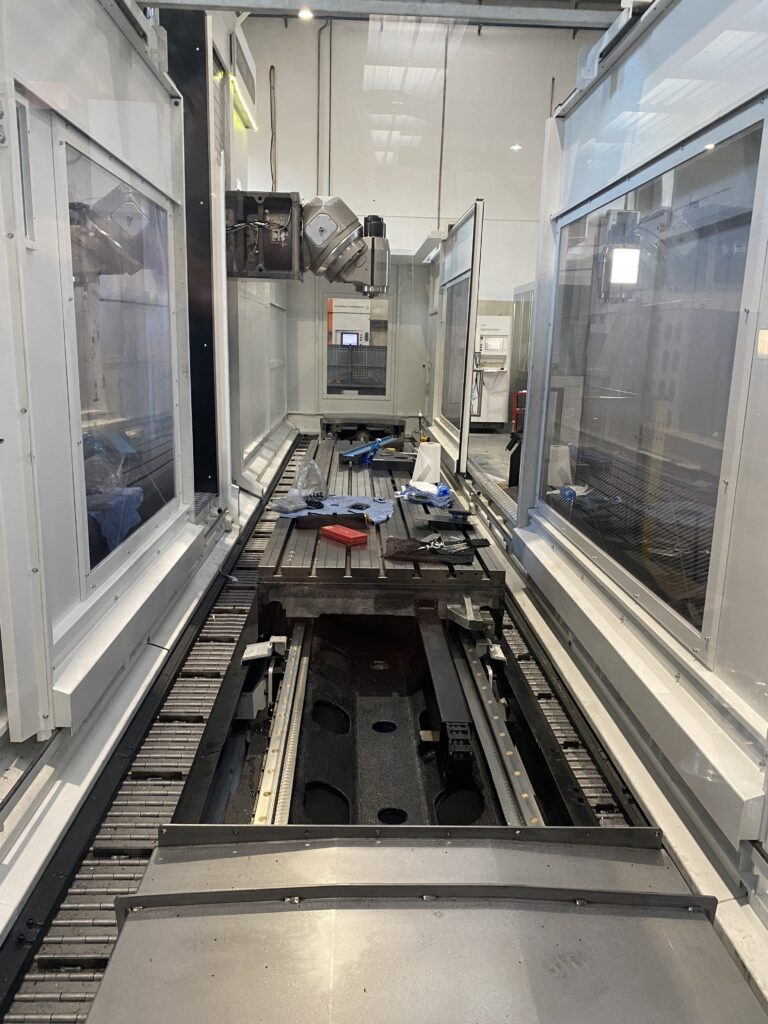

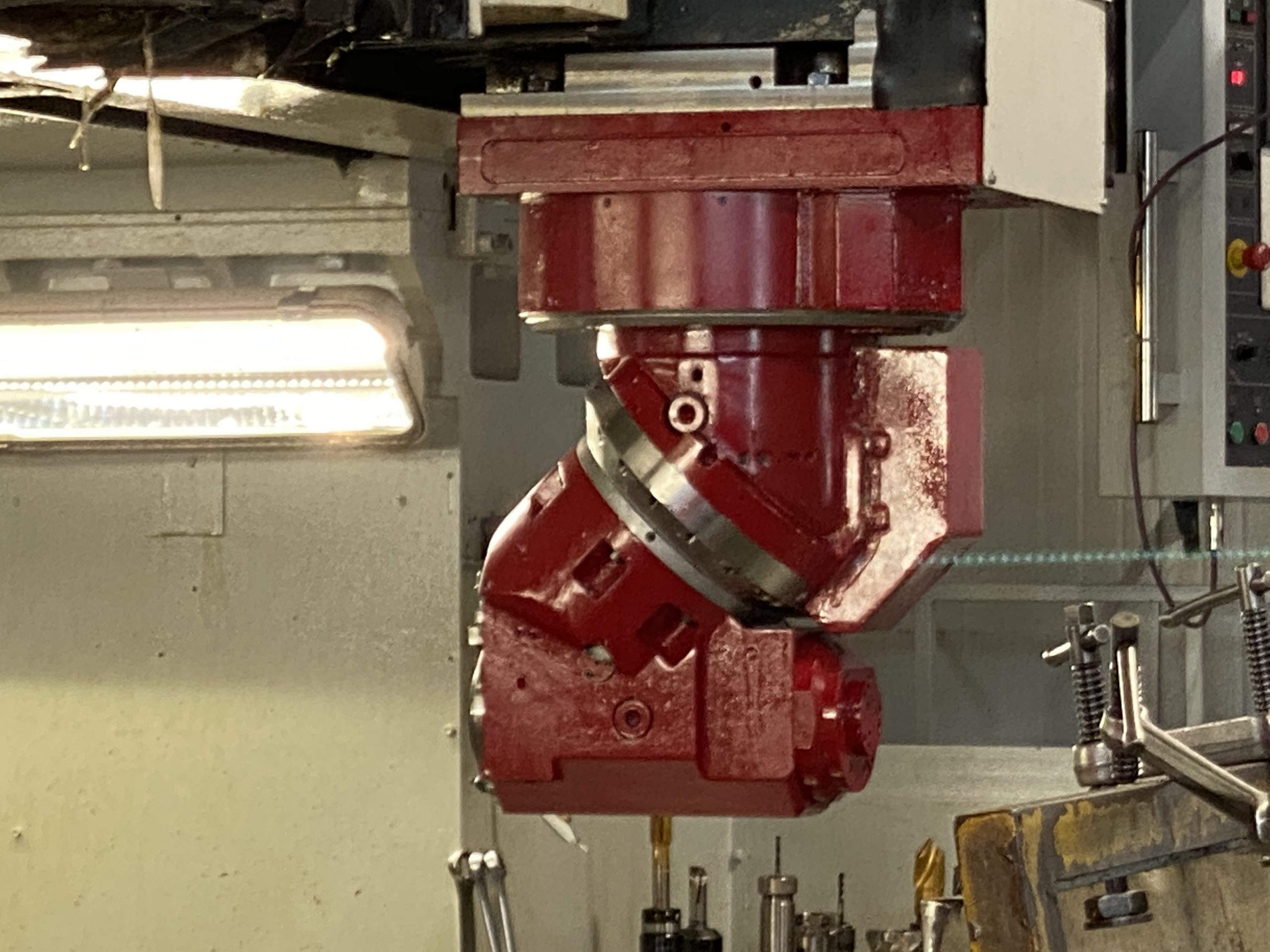

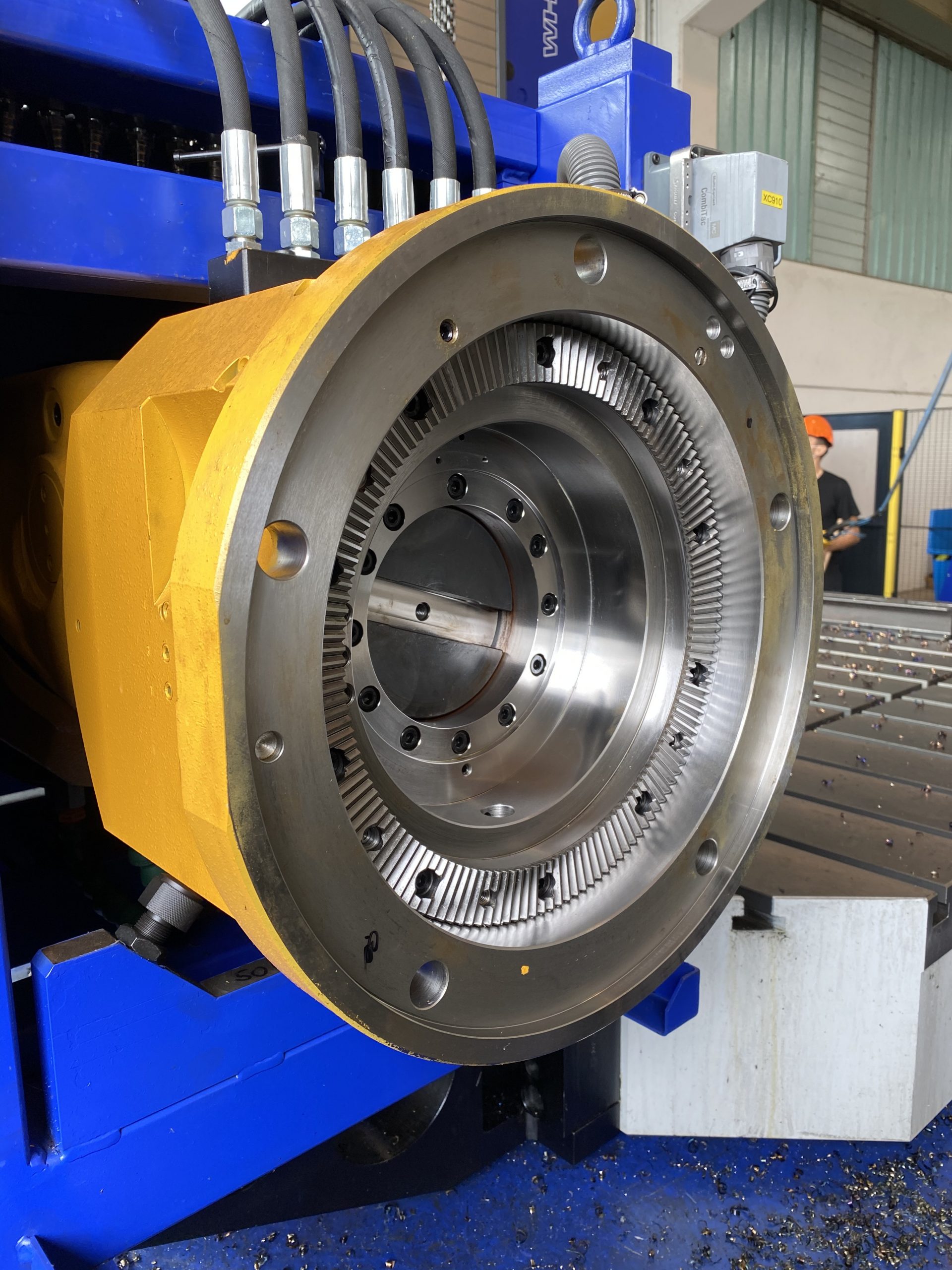

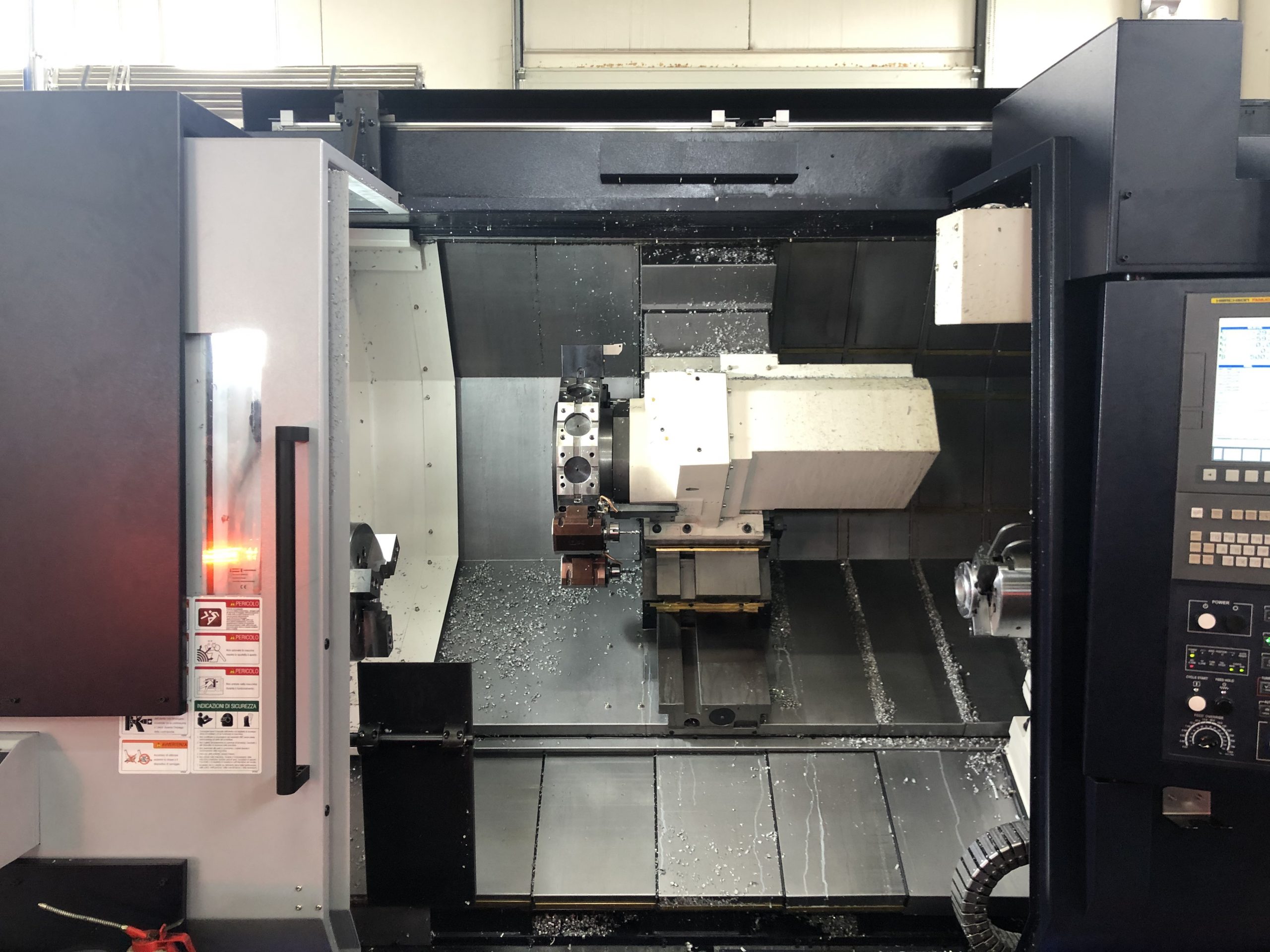

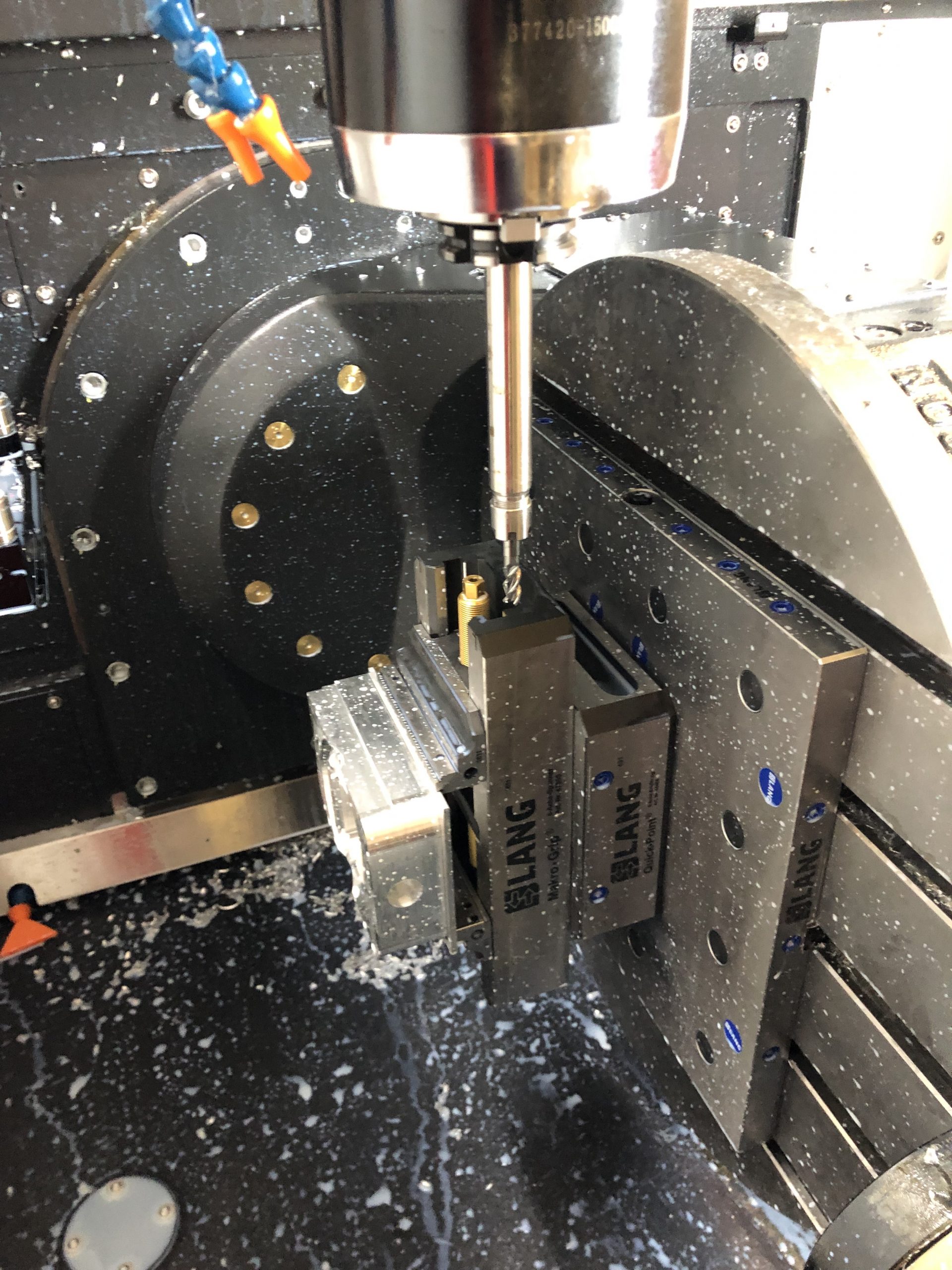

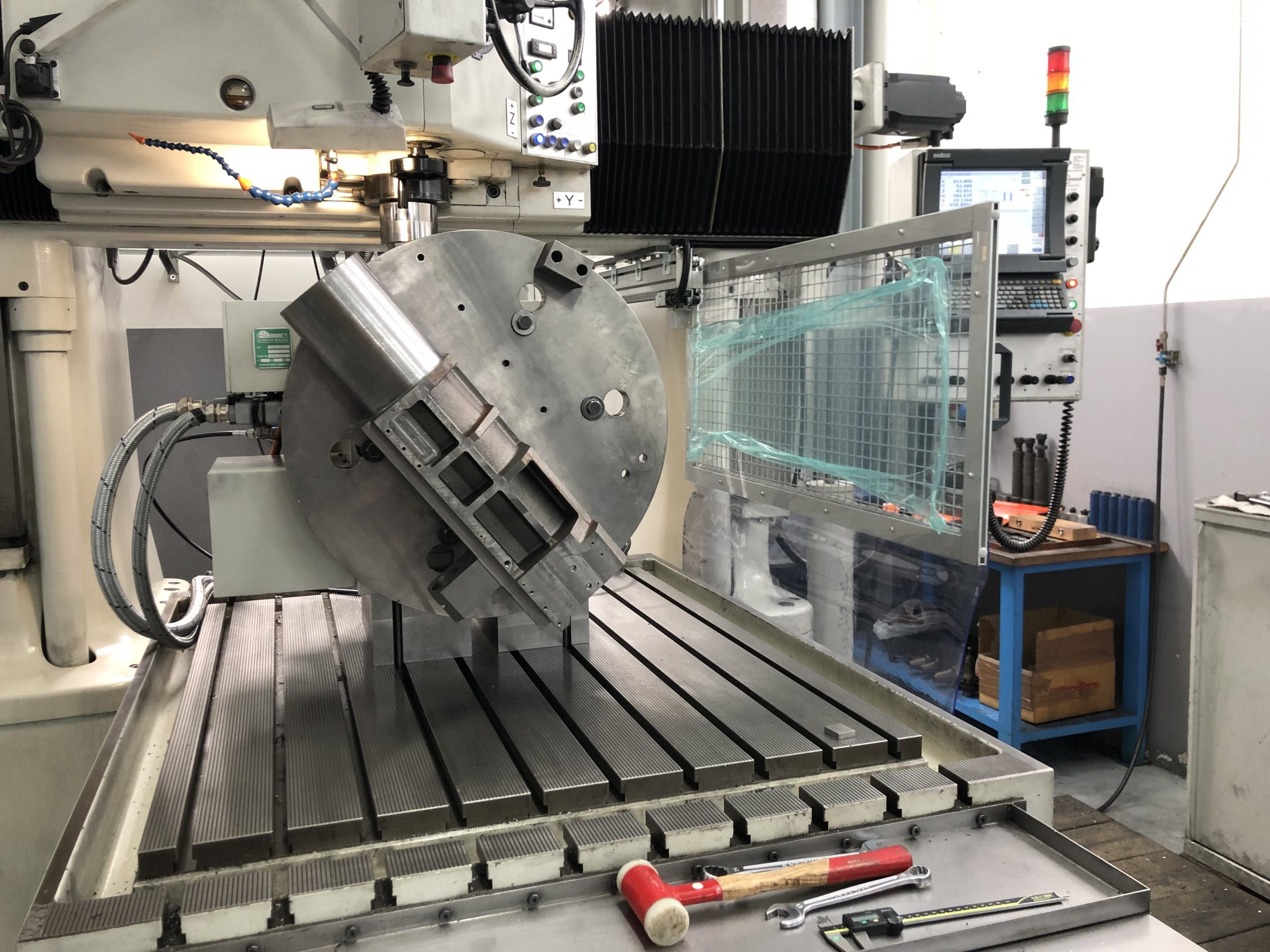

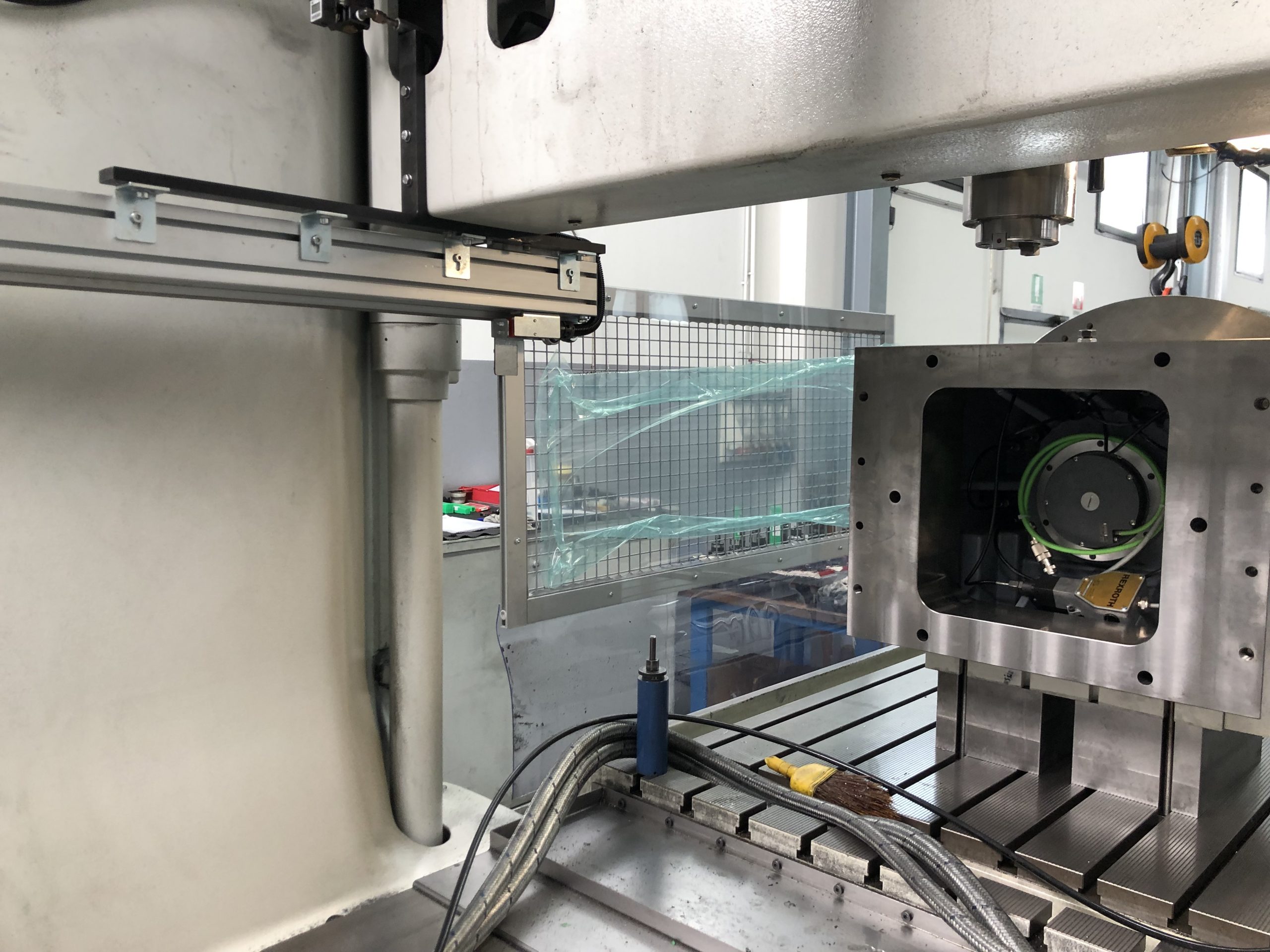

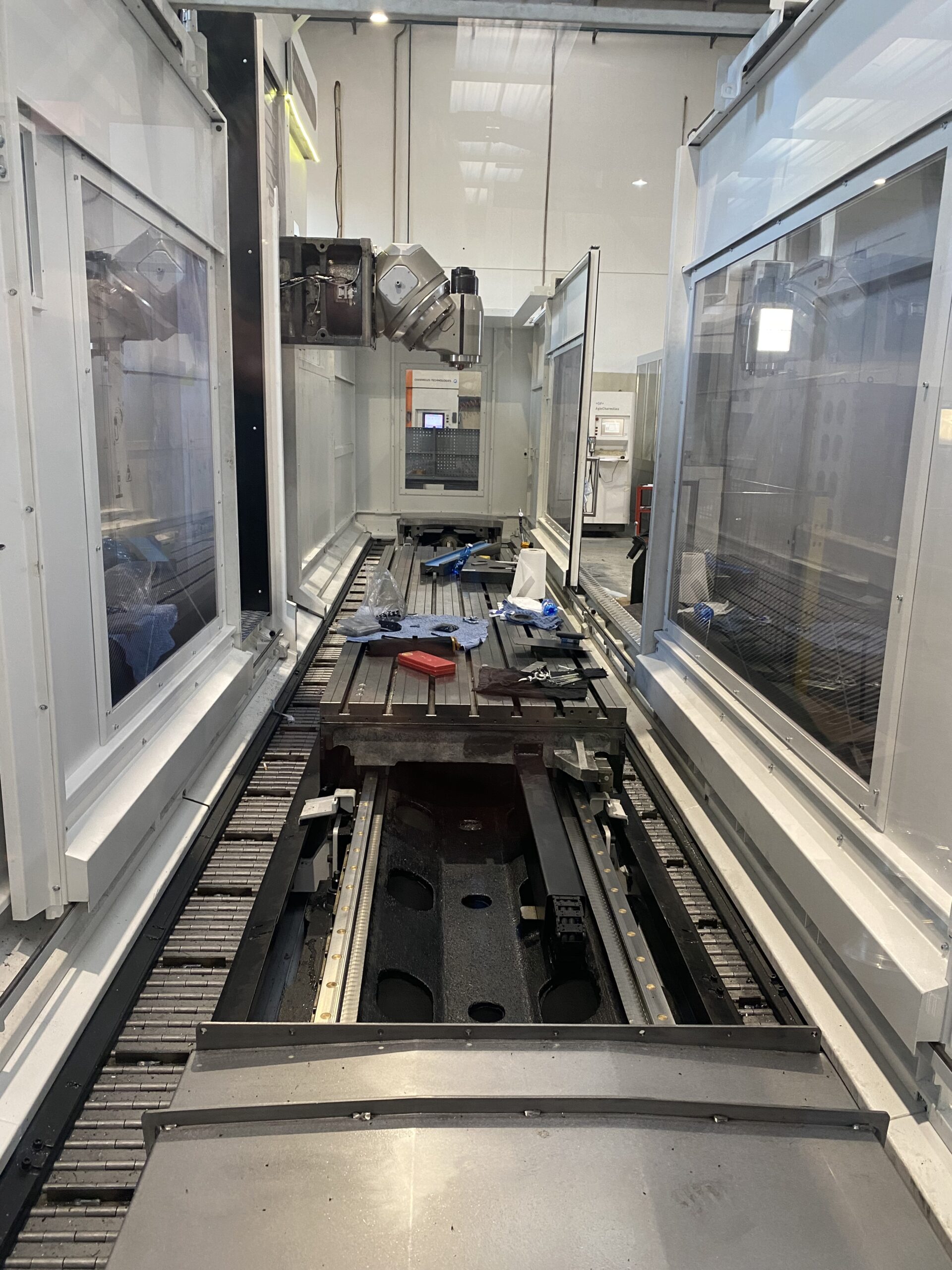

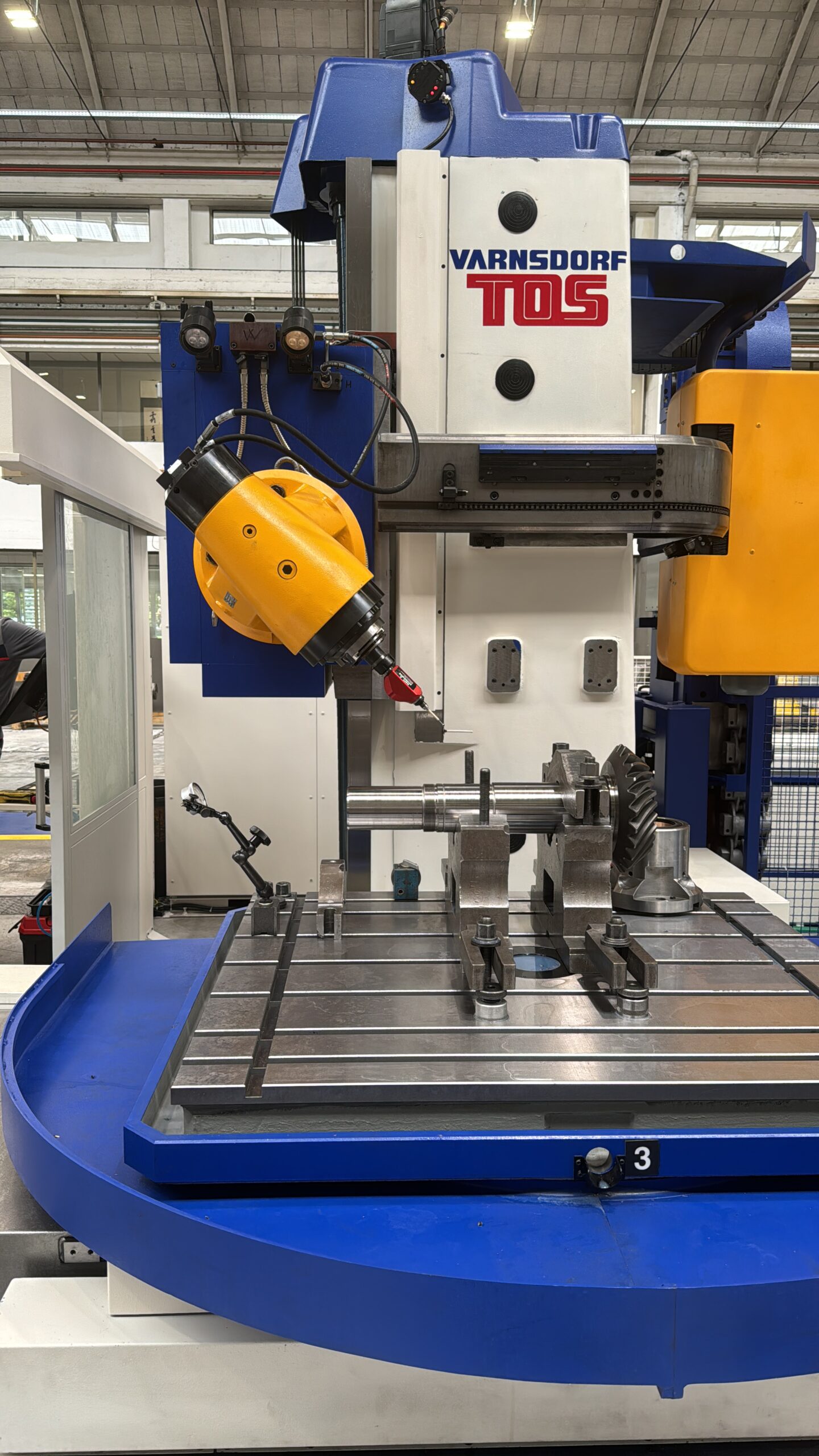

Assistance on large machining centers.

For CNC machines with mobile or gantry columns, with worktables from 3 to 30 meters, we have the capability to perform installations, leveling, and Cartesian geometries on the axes using granite rulers and squares, digital electronic levels, interferometric lasers, or geometric lasers. Overhaul of orthogonal heads (rotary-tilting axes). Geometric control of the Tool Centre Point (TCP). Kinematics.

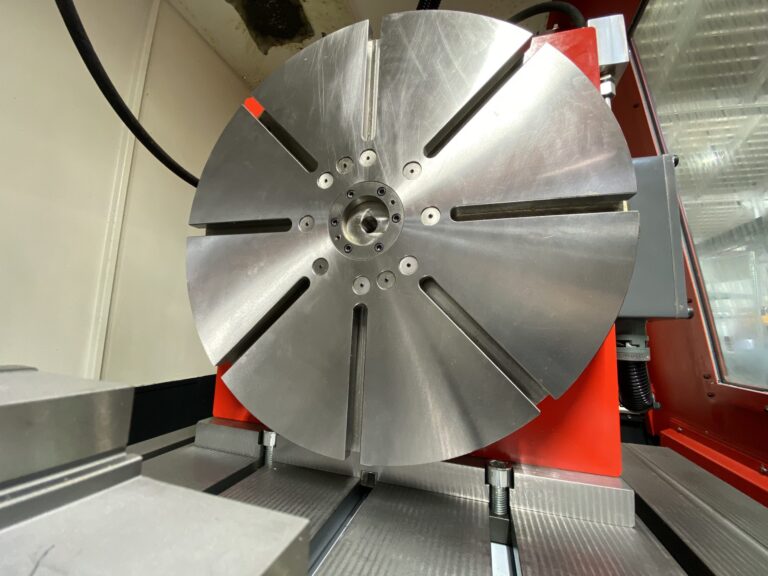

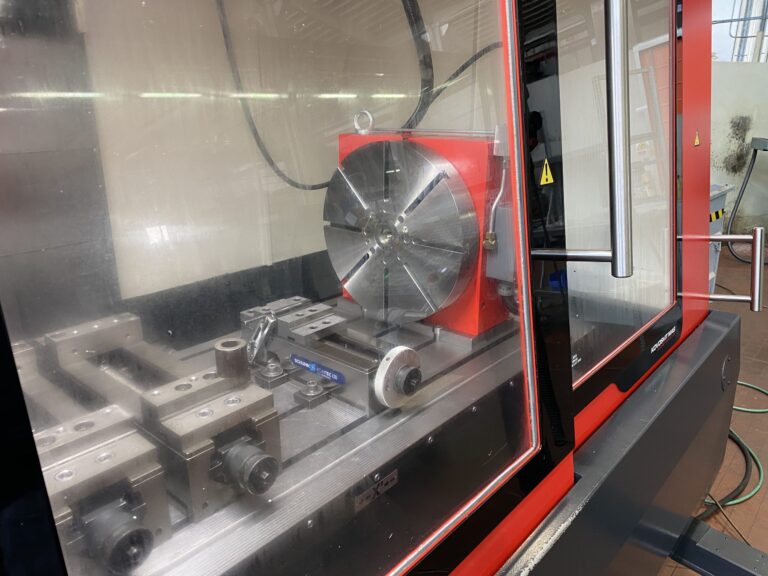

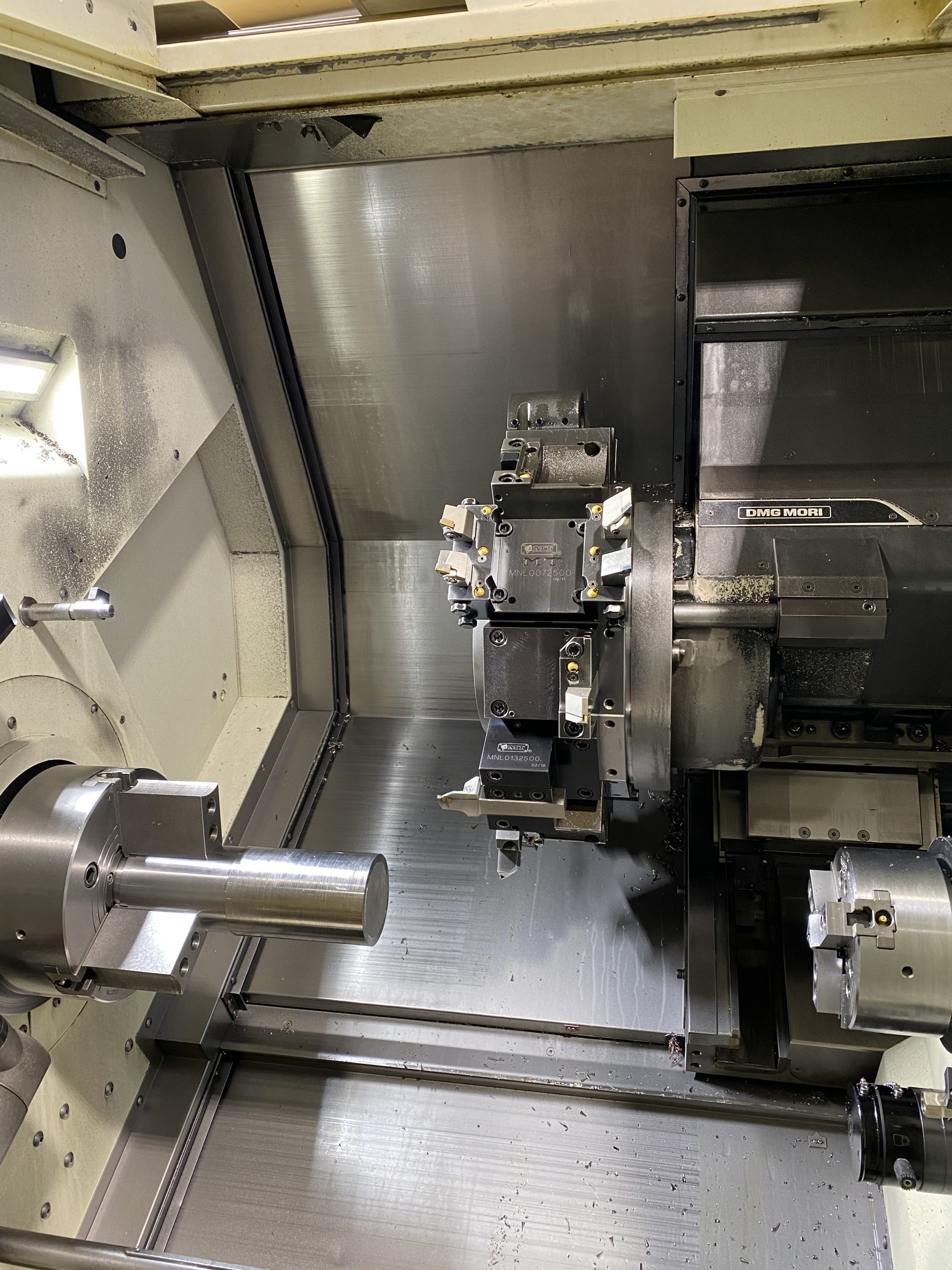

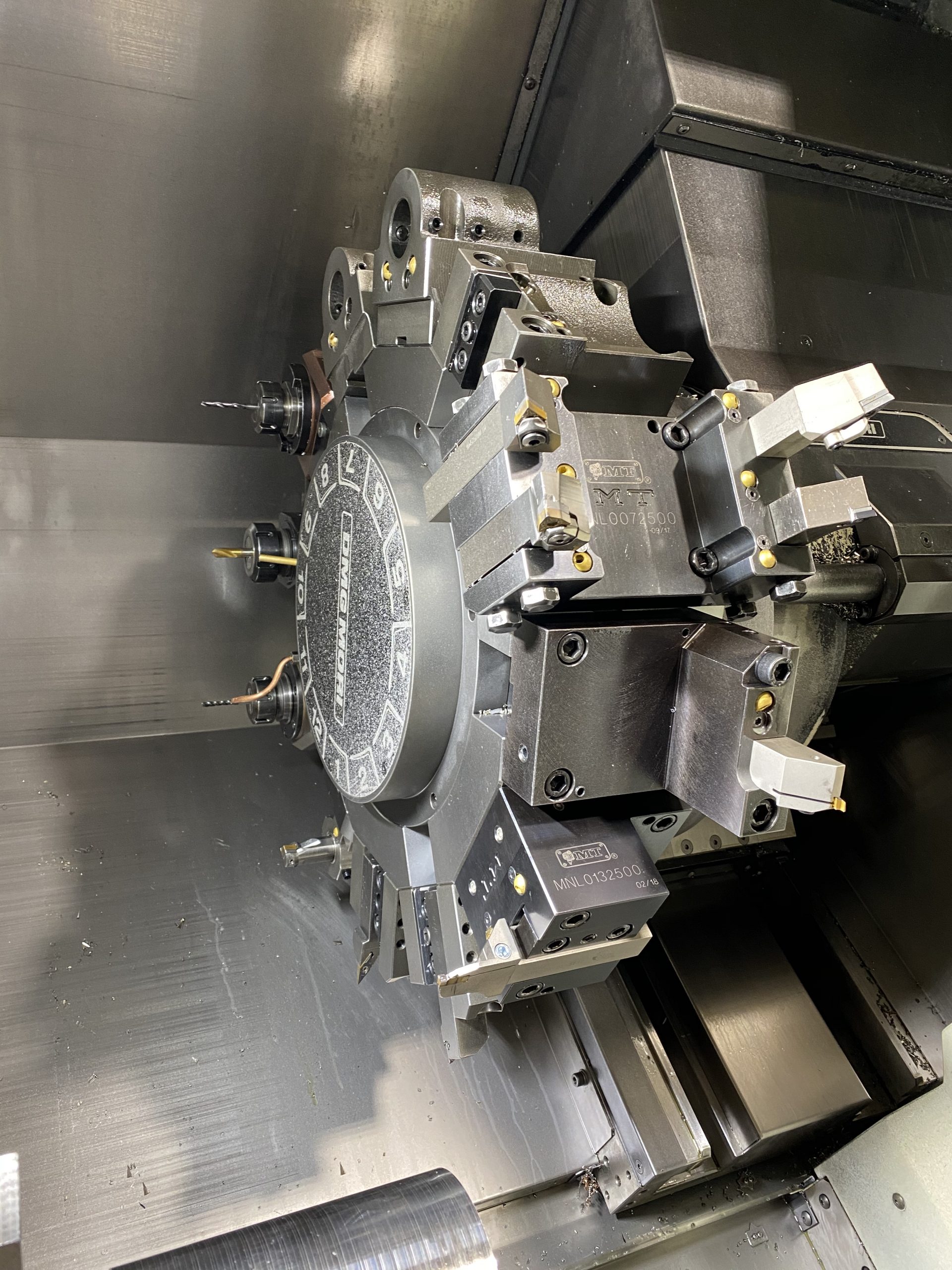

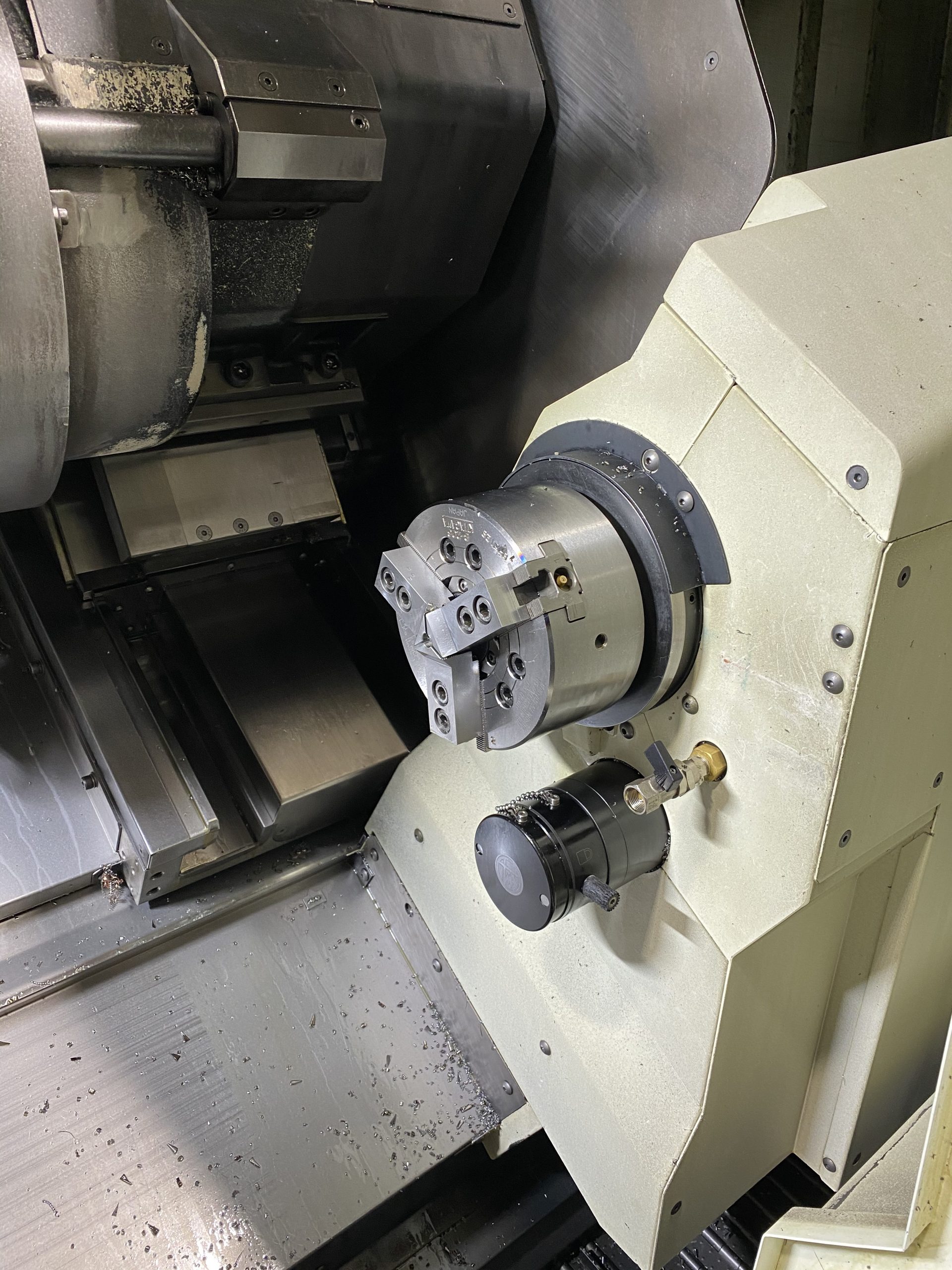

Assistance with turning operations.

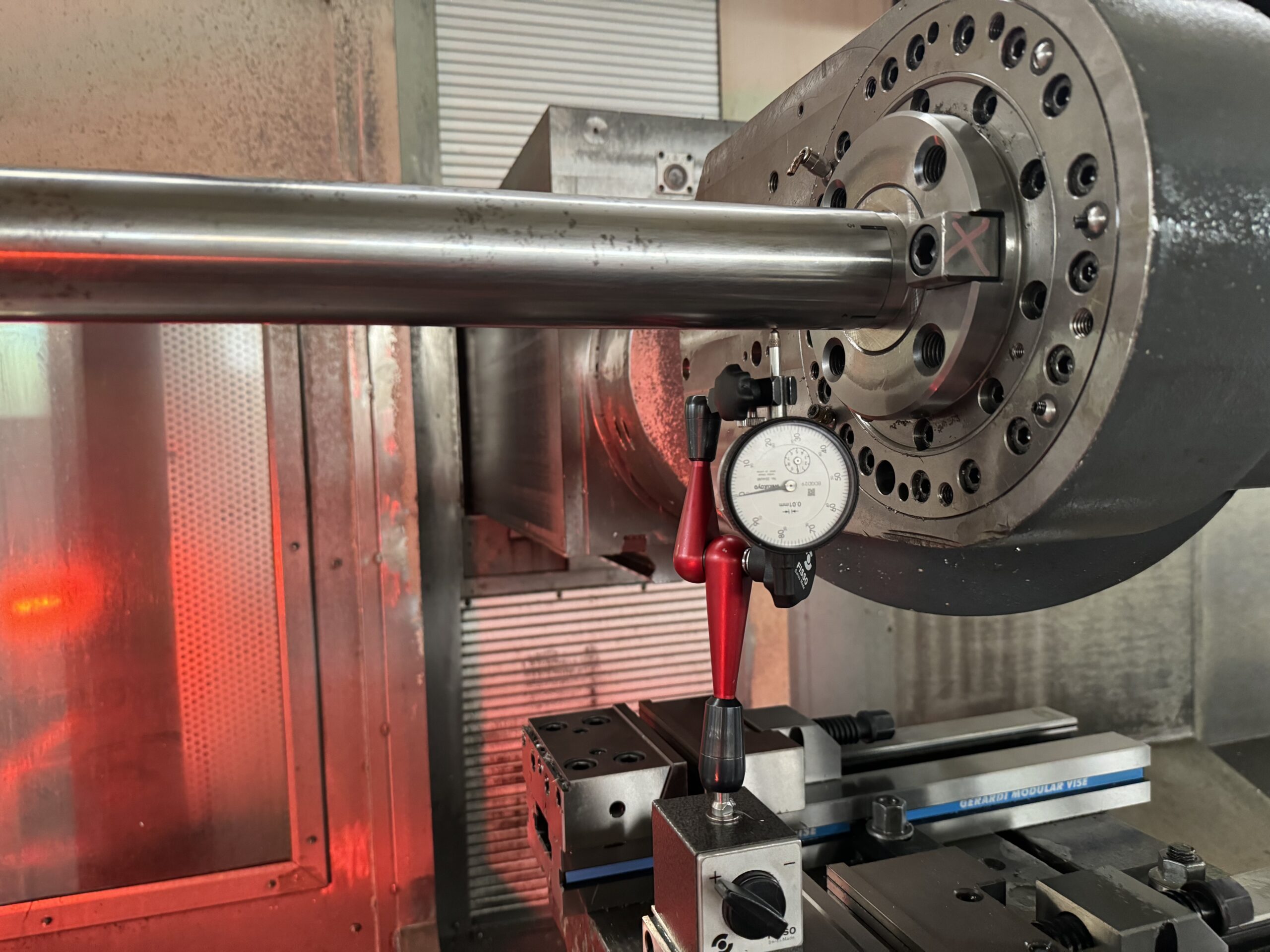

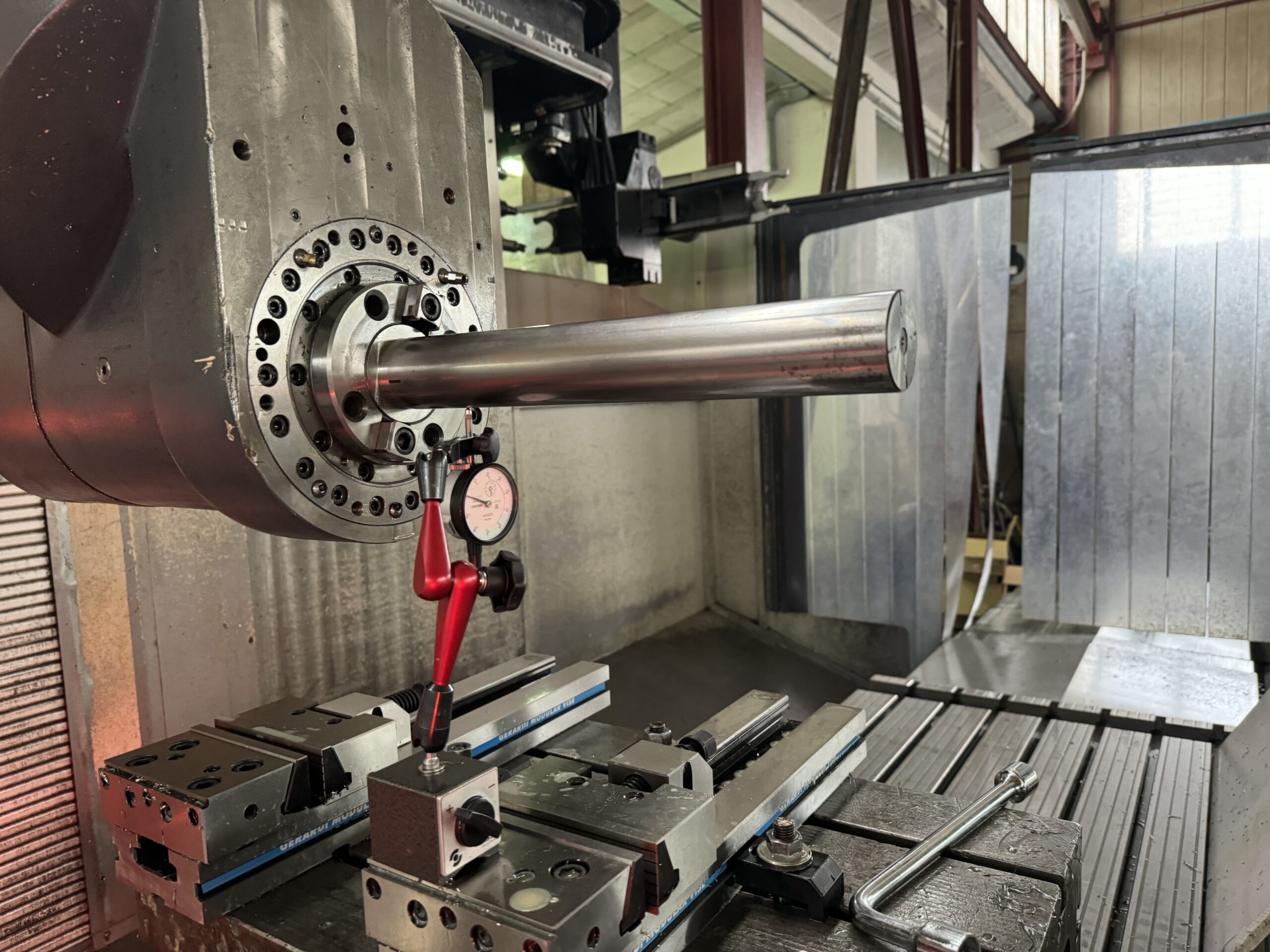

Geometric alignment between axes and turret.

Geometric alignment of the turret tool holder plate.

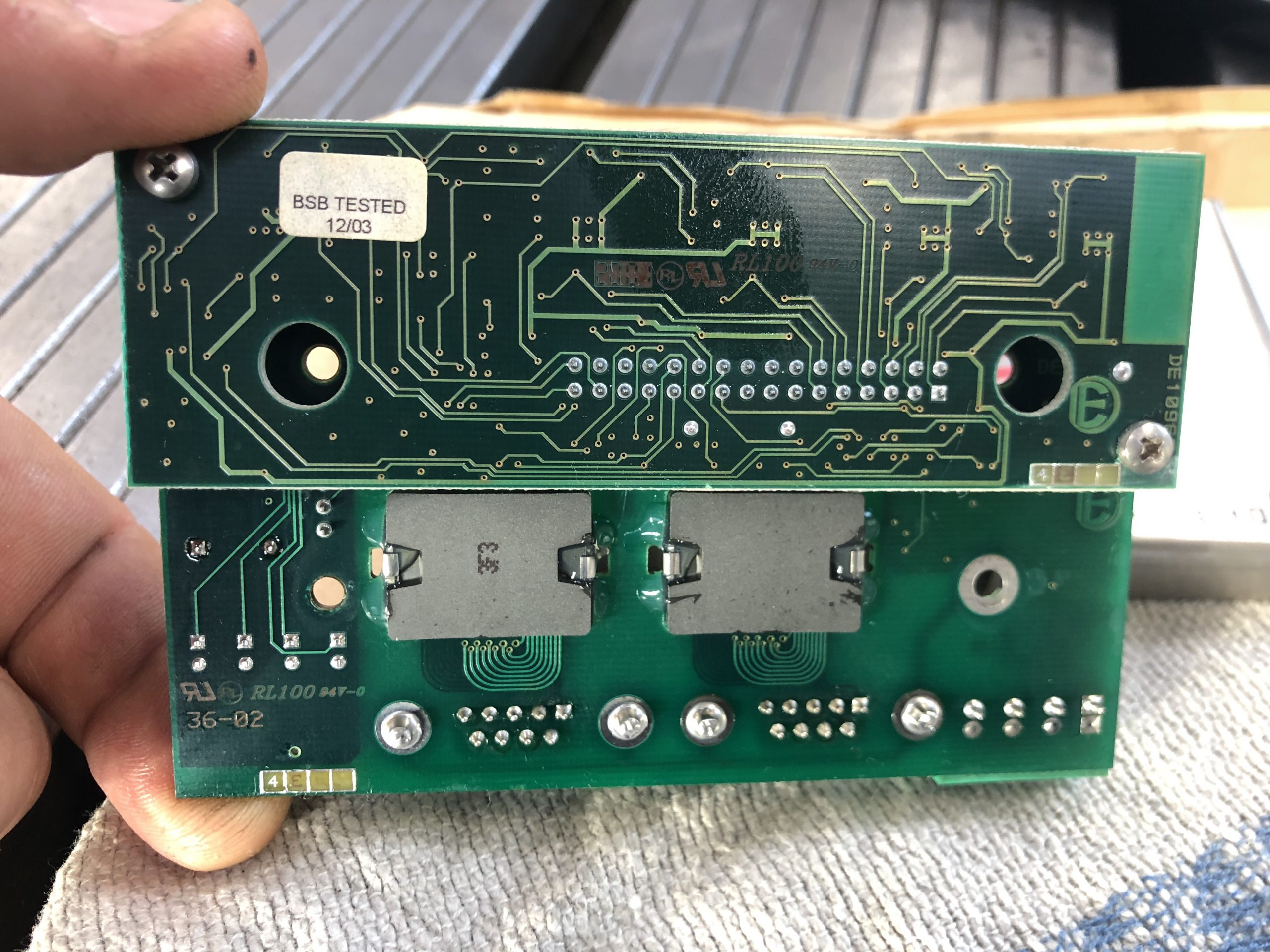

Electrical and mechanical overhaul of the tool turret. We specialize in Baruffaldi and Duplomatic. Internal testing of the turret with an electronic rotation and cycle control bench.

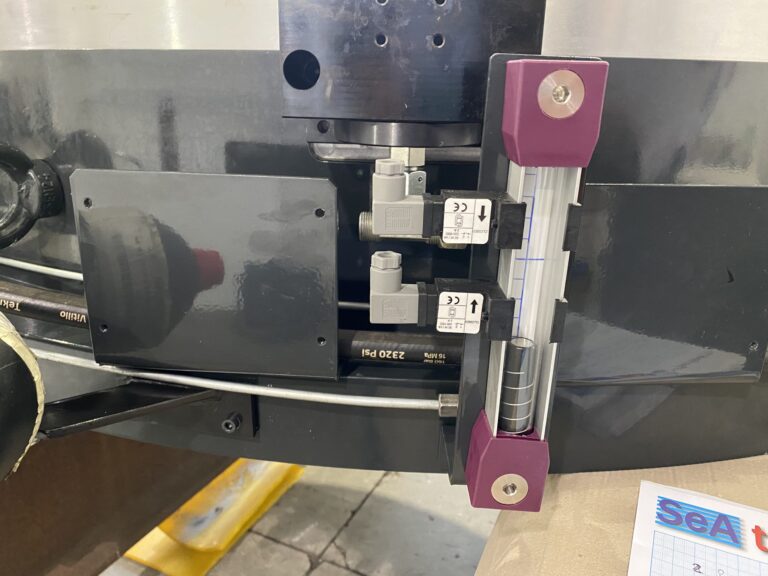

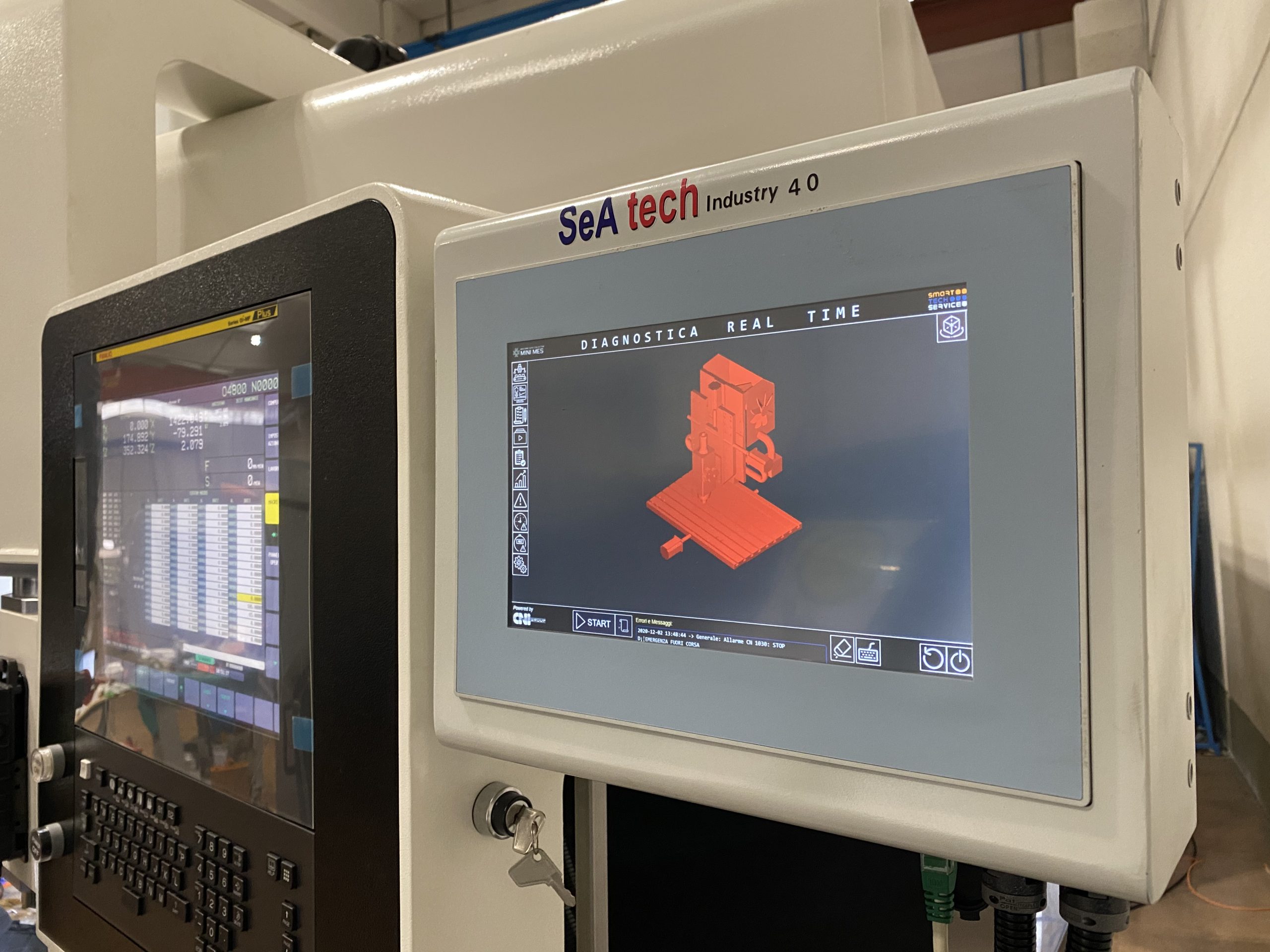

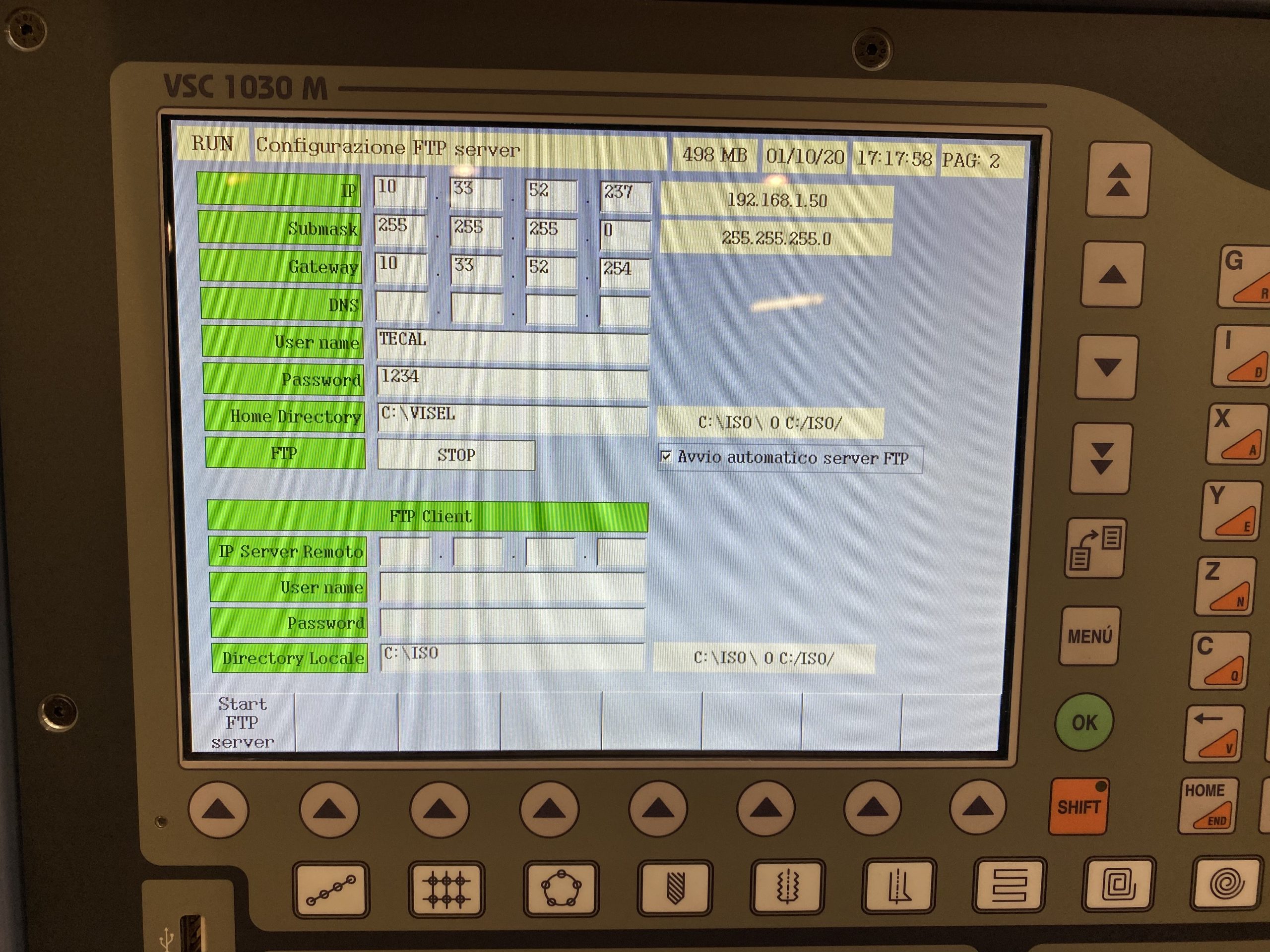

Installation of interface system for I4.0.

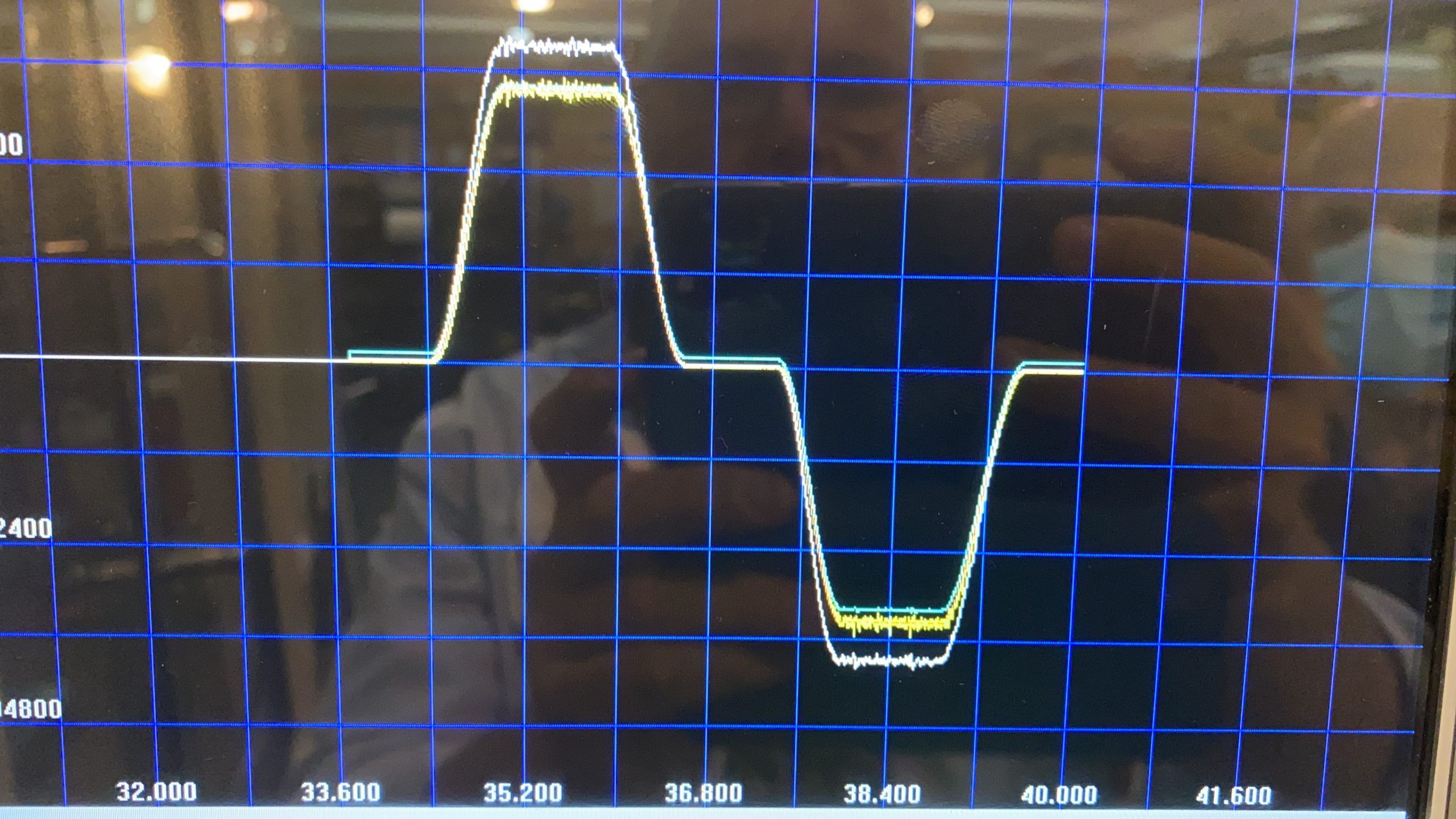

SeATech, in collaboration with Romagna Servizi (Confindustria), CNI, and Botika, has developed a CNC machine supervision system called MDC (Machine Data Collector), later renamed S.A.M. The system interacts with the CNC, extracting all the necessary digital data for plant supervision via MES software installed on the MDC, and transfers it to the company’s management system. We monitor the active program, the number of pieces to be executed, the number of pieces completed, the total cycle time, the time taken per piece, the machine setup time, the piece change time, all motor currents of the axes and spindle (consumption in Amperes or percentage), monitoring the efforts. We control motor temperatures, axis and spindle bearing temperatures, axis and spindle vibrations, and any collisions, providing data for predictive maintenance. The system also communicates with the web, sending alarm or anomaly notifications directly to your mobile phone.

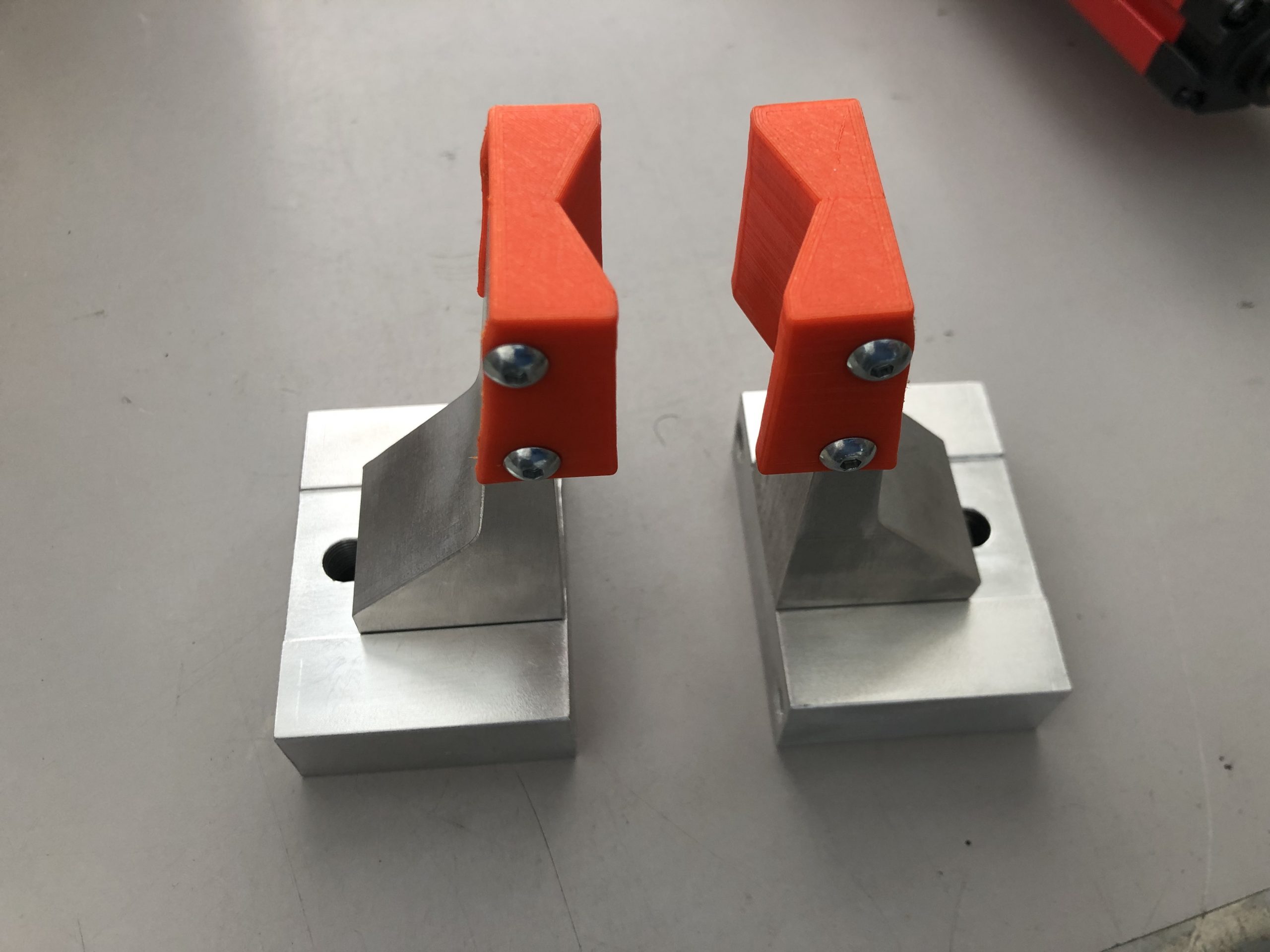

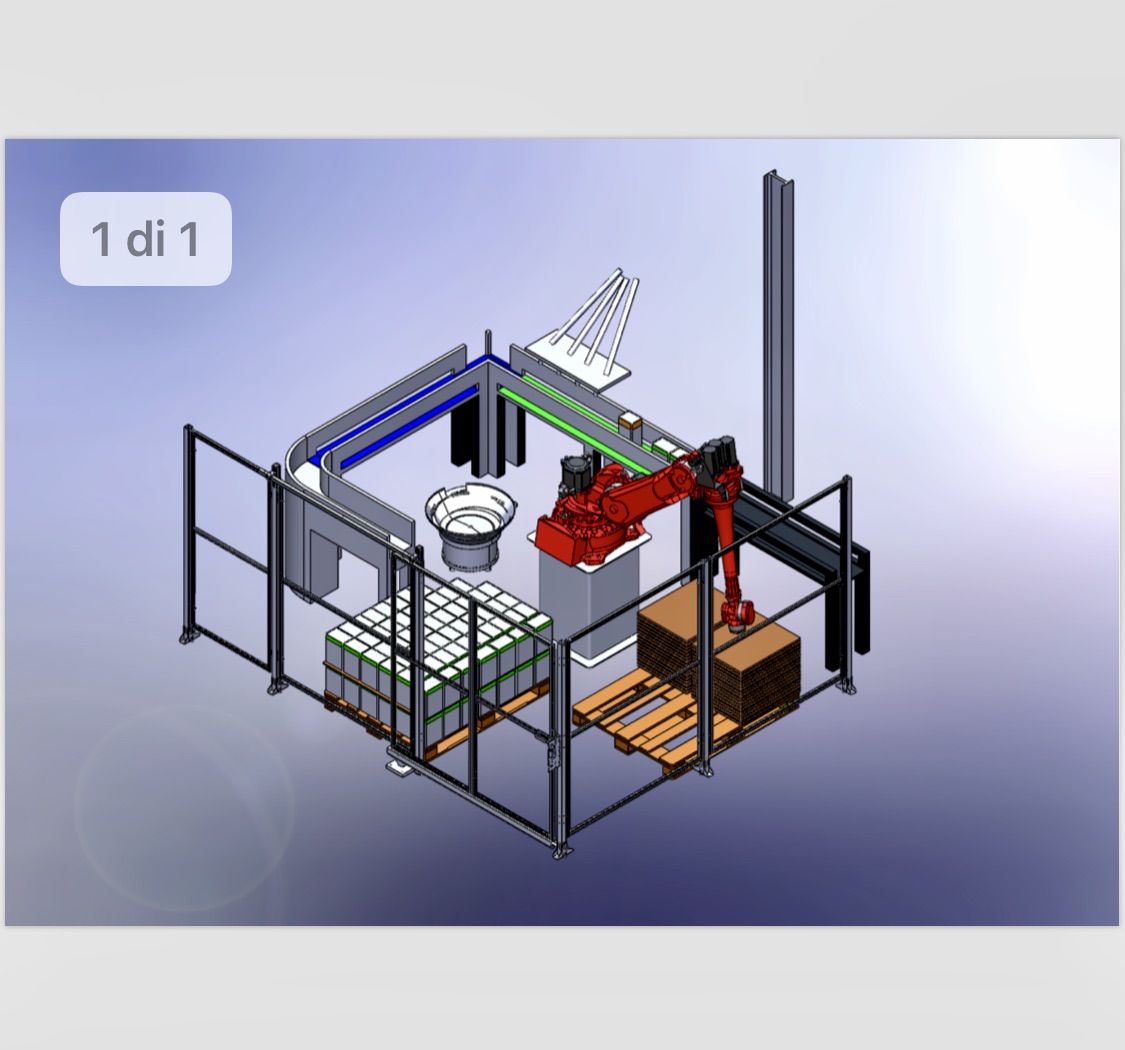

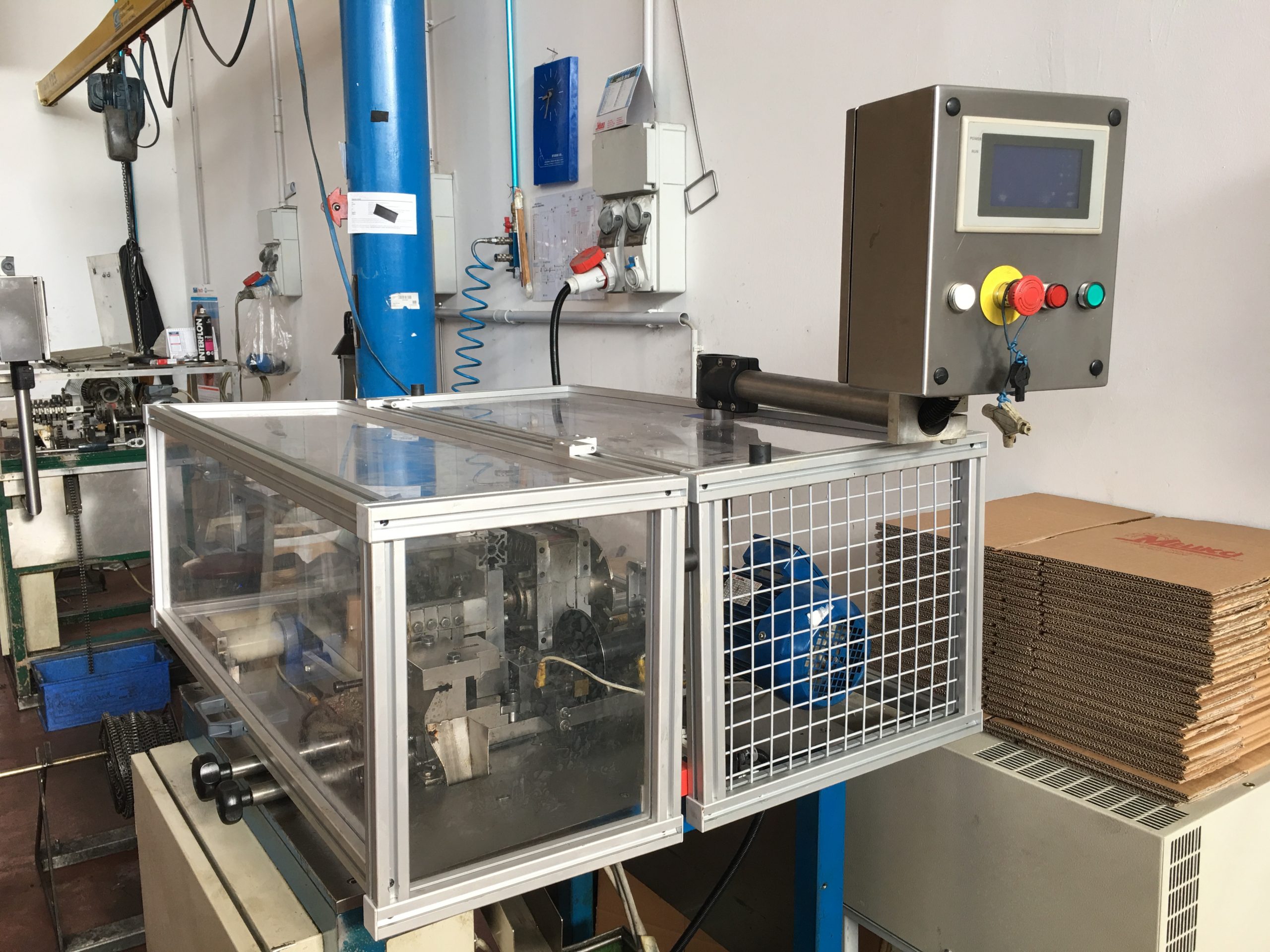

Special Machines and Equipment

On commission, SeA tech is capable of developing special plants or machines for the creation of work cells. These include piece marking cells, handling systems, electromechanical management of high-speed spindles, special benches for testing spindles or motorized tools, and machines for thermoplastic molding.

Geometric Controls

Geometric controls are essential to ensure the precision and accuracy of mechanical operations. SeATech offers advanced geometric control services to verify that components and structures meet design specifications. We use high-precision measuring instruments to detect any geometric deviations, ensuring that each piece produced adheres to the highest quality standards. These controls are crucial for preventing manufacturing defects and ensuring the full functionality and reliability of finished products.

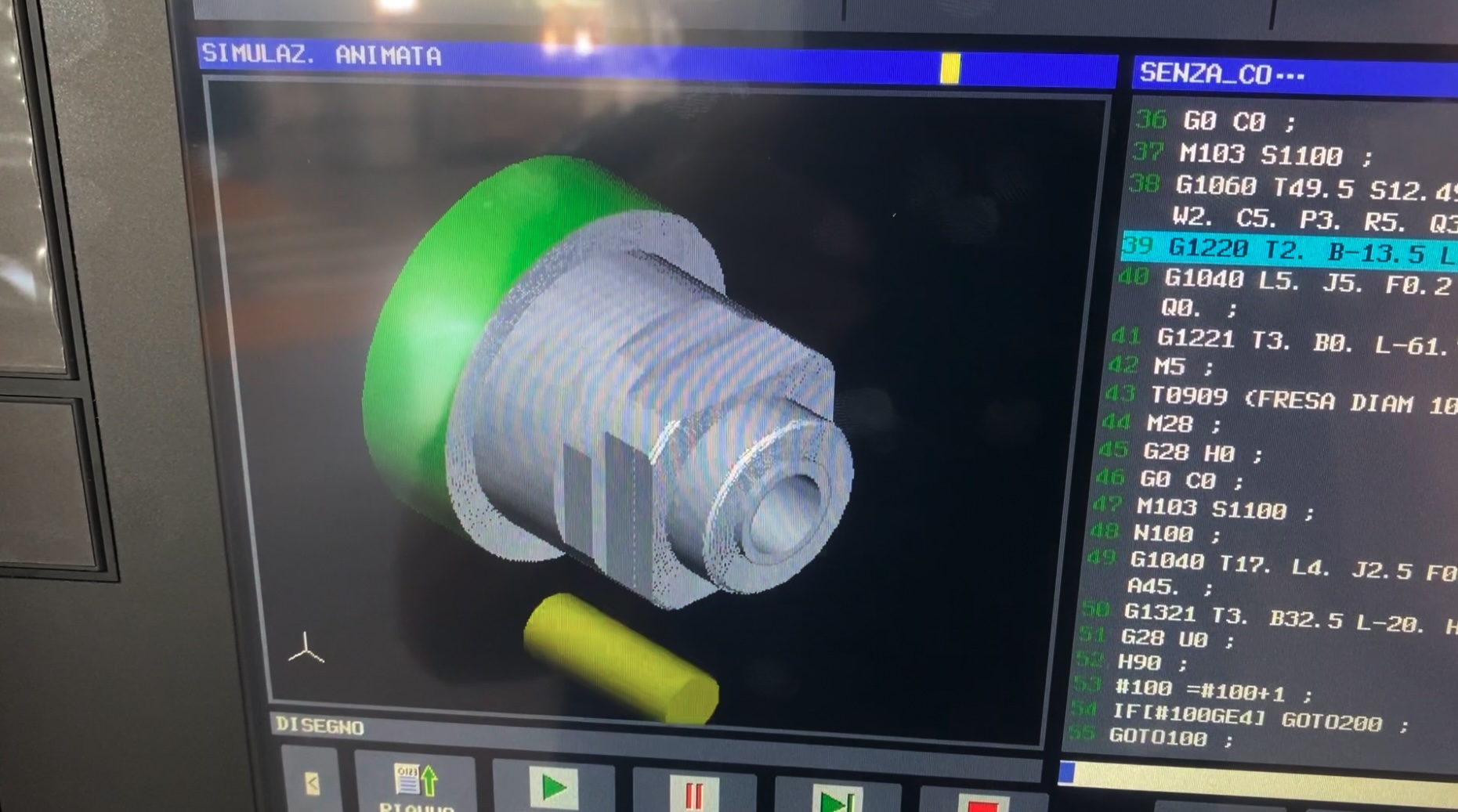

Programming Courses

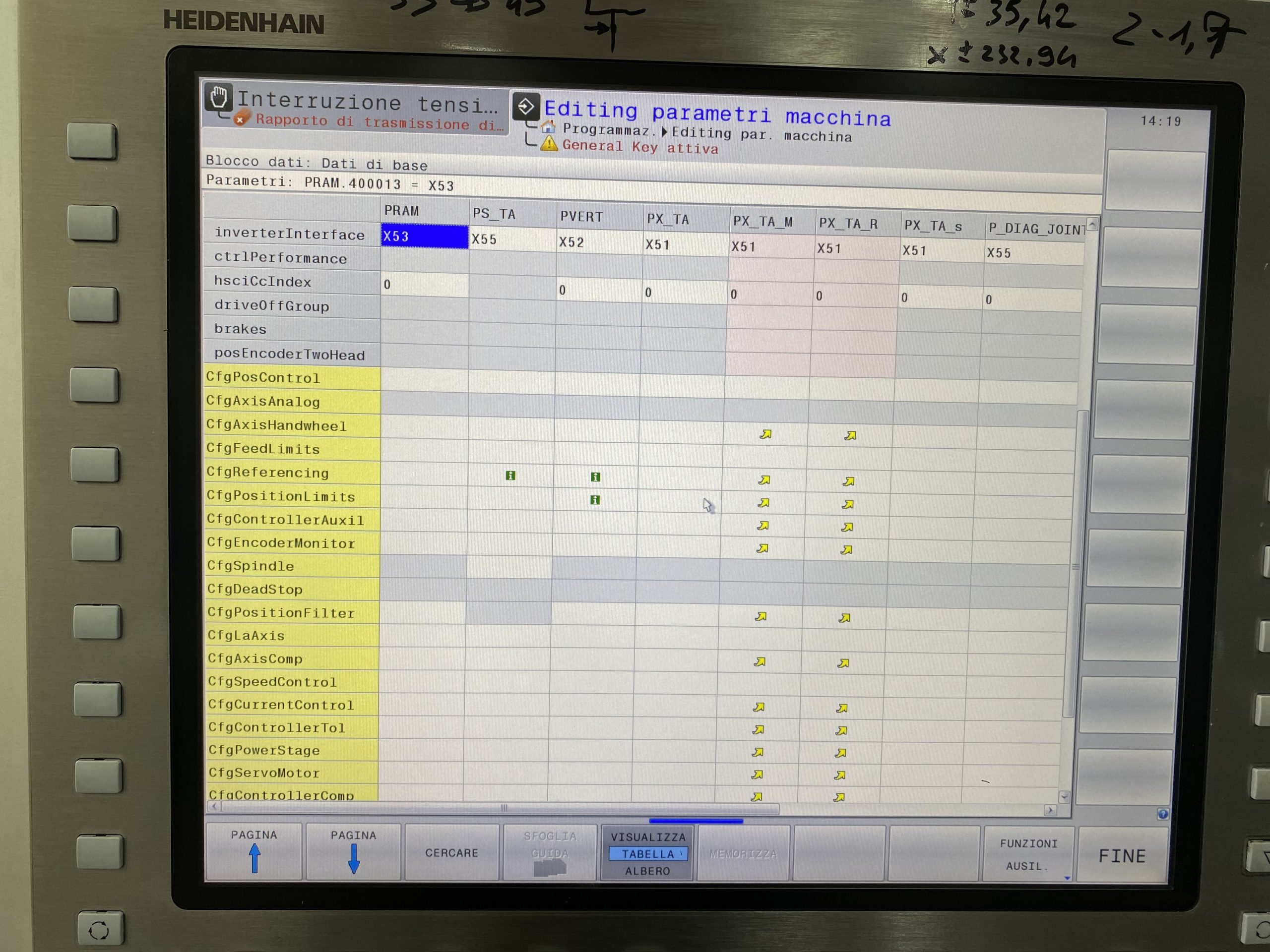

SeA tech offers its expertise in conducting CNC programming courses for milling or turning using controls such as Heidenhain, Fanuc, Visel, Mitsubishi, and Fagor. Courses cover 3-axis or 5-axis operations with the use of software like Fanuc’s Manual Guide i or Heidenhain’s plain text language directly on the machine or using programming and simulation stations.

We also provide programming courses for Yaskawa or Fanuc robots. With a practical and market-oriented approach, participants gain the necessary knowledge to optimize production processes and improve operational efficiency in their companies.

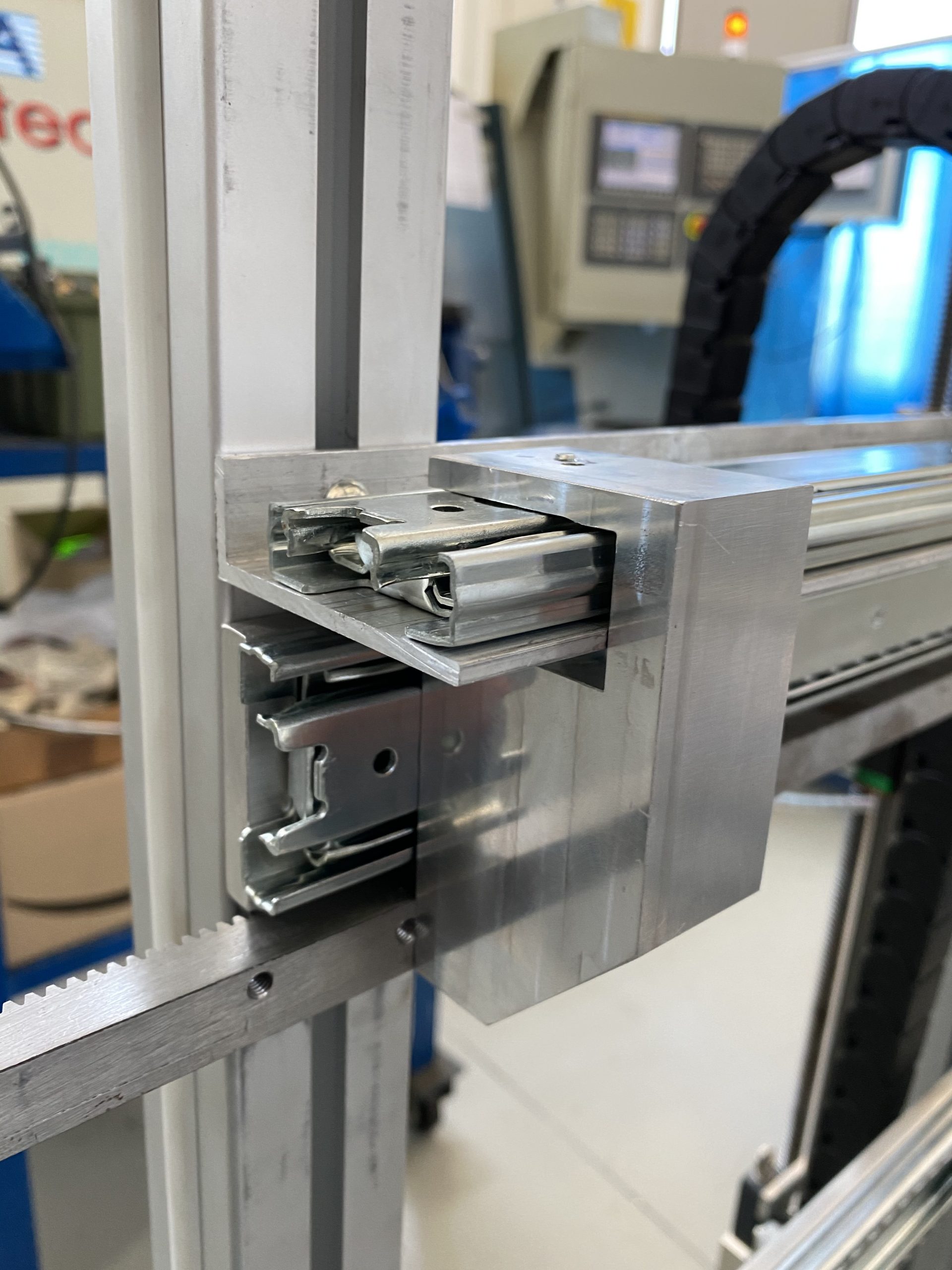

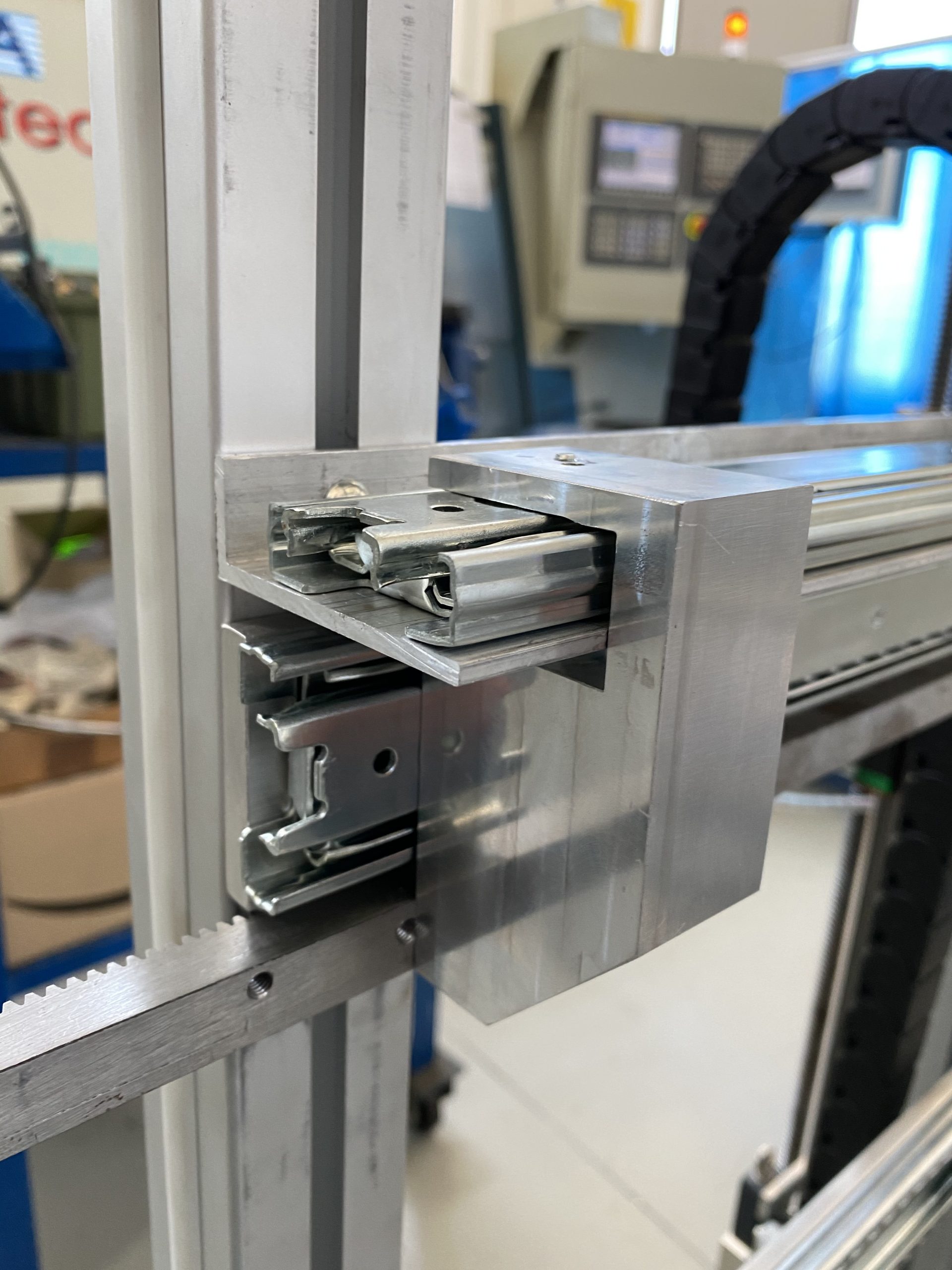

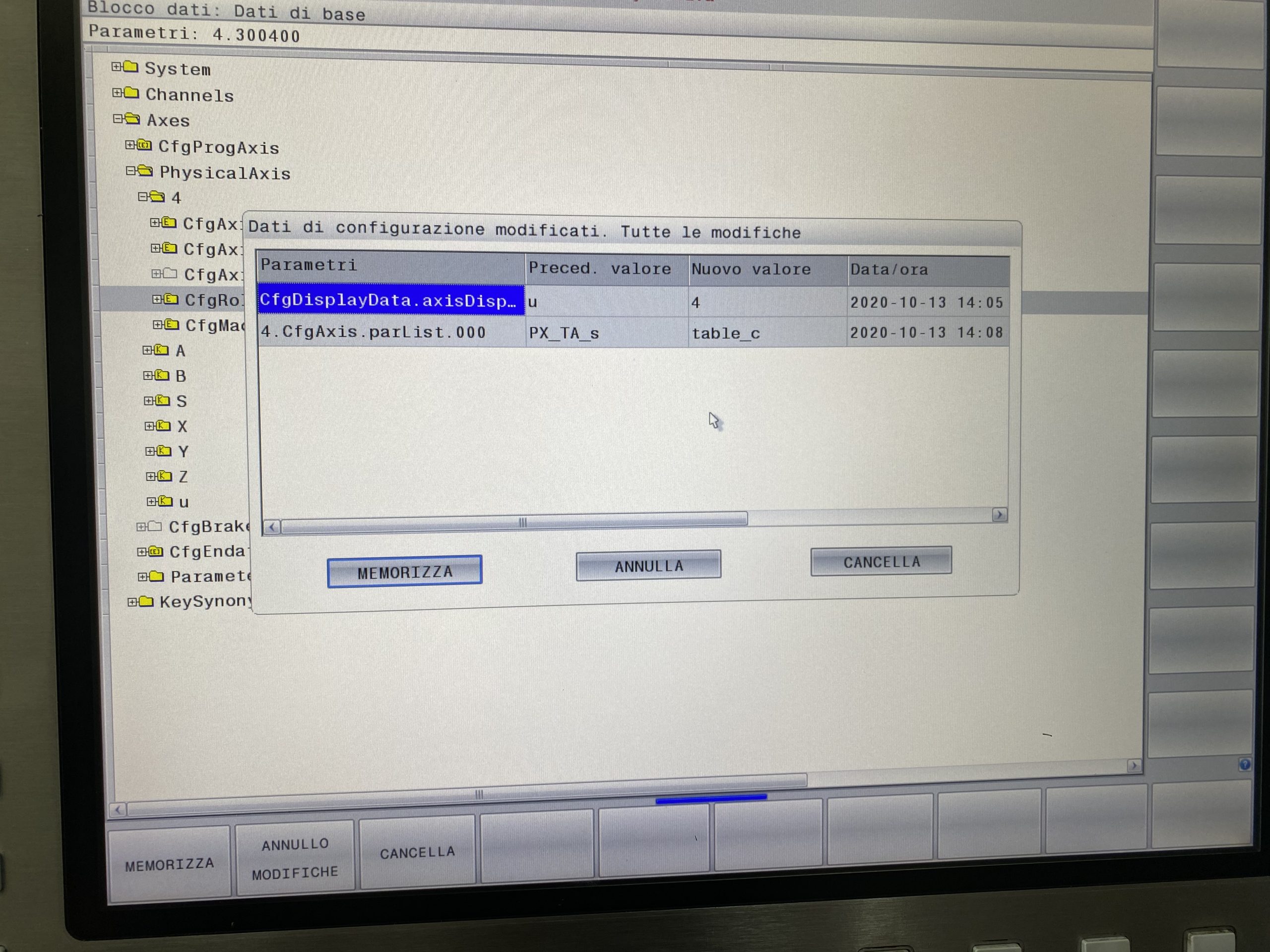

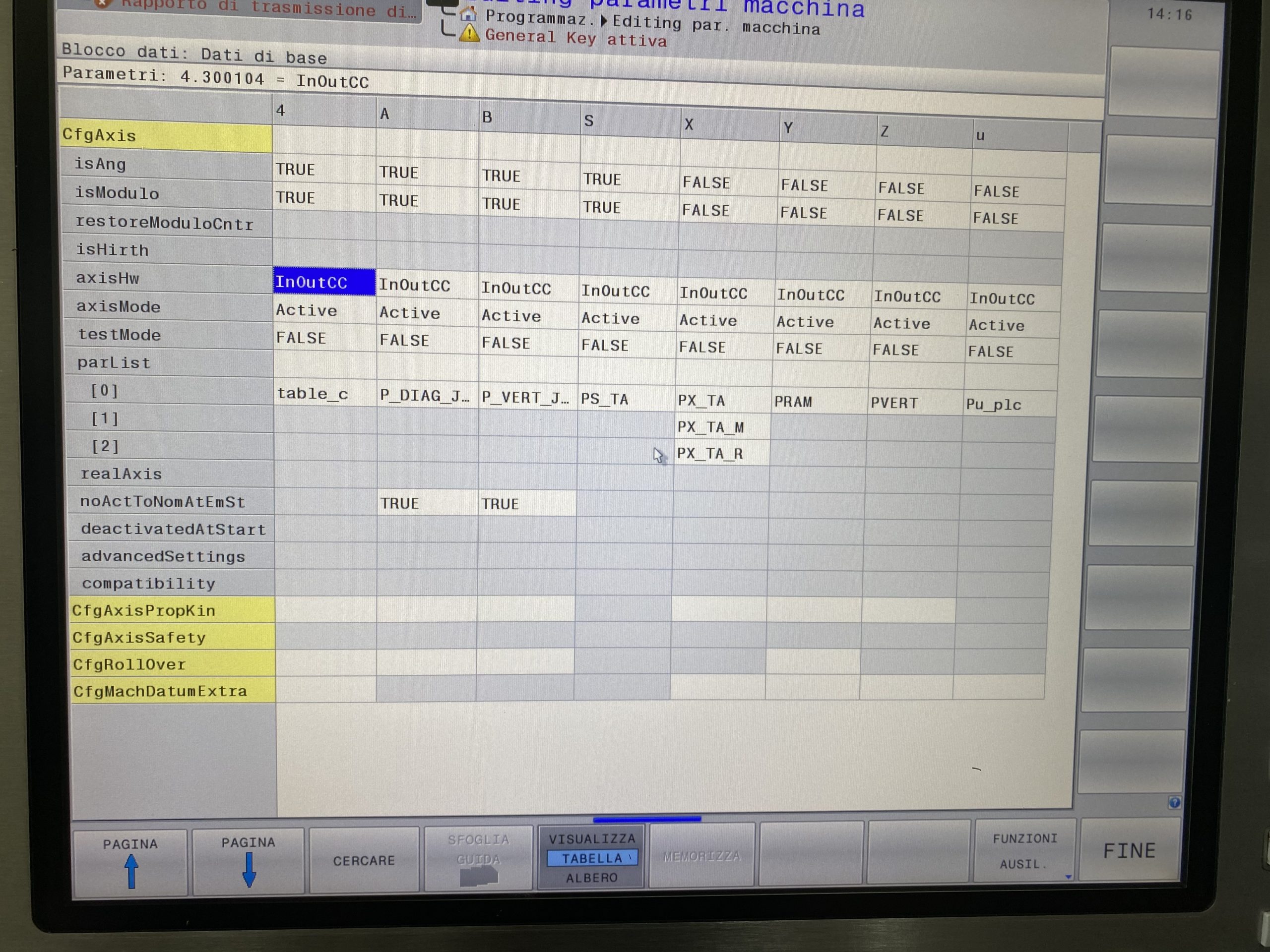

Installation of Additional Axes

The installation of additional axes is an essential service to enhance the flexibility and capabilities of machine tools. SeATech specializes in integrating supplementary axes, which expand the range of operations and increase the precision of manufacturing processes. With our experience, we customize each installation according to the specific needs of the customer, ensuring a perfect fit and improved operational efficiency. This upgrade is ideal for companies aiming to optimize their production lines and remain competitive in the market.

Service First

SeA TECH di Emmediemme srl

SeA tech is known nationally thanks to its ongoing collaboration with the largest groups that have occupied the main showcase of the Automation sector for years. Among these, we mention Fanuc, Heidenhain, and Siemens.