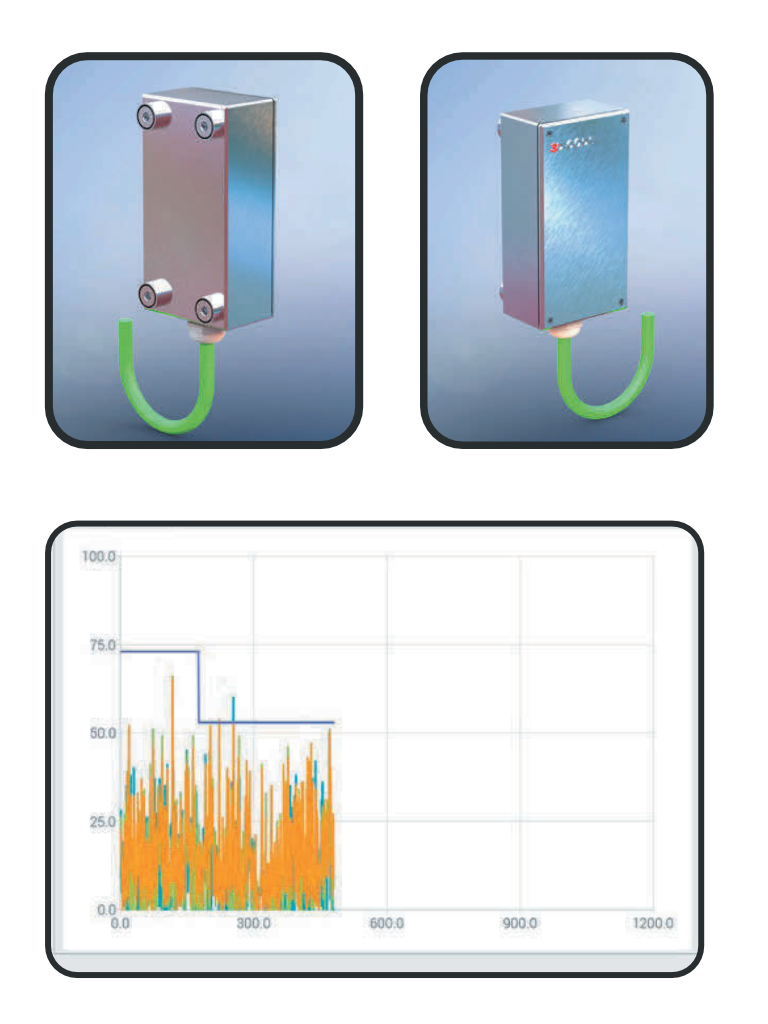

3D CO.DE. TRIDIMENSIONAL COLLISION DETECT

It is a single sensor installed near the tool spindle of the machining center, lathe, or robot, which allows real-time monitoring of the machining status of the machine tool, detecting every vibration coming from the working tool so that you can monitor the following characteristics:

The ease of installation and the competitive budget of 3D CODE make it accessible even to small and medium-sized enterprises.

The user interface is simple and intuitive. It requires a basic Windows PC connected to the network and does not need to be specifically dedicated to monitoring activities alone.

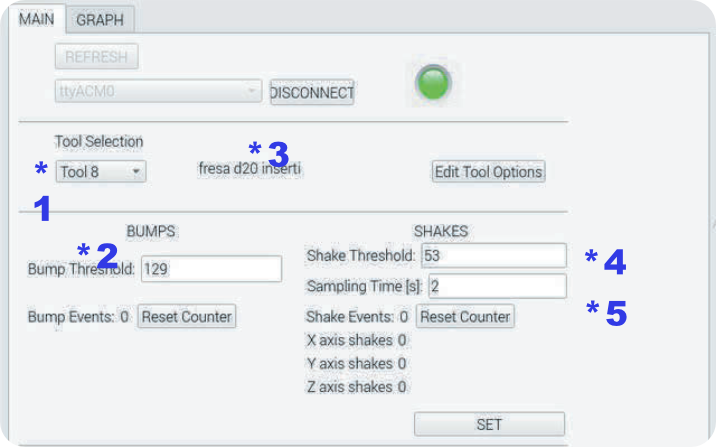

1) ACTIVE TOOL

2) IMPACT THRESHOLDS

3) TOOL NAME

4) VIBRATION THRESHOLDS

5) VIBRATION EVENTS

Higher attention thresholds can be set to filter out SPIKES (peaks due to hard spots detected in material castings) for the threshold of:

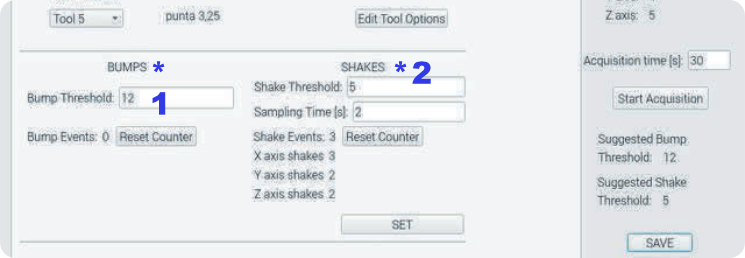

It operates with self-learning, storing the curves of 127 tools across three ranges of work types:

The message can stop the machining process or not, depending on the user’s settings.

The user interface is simple and intuitive.

It requires a basic PC connected to the network and does not need to be specifically dedicated to monitoring activities alone.

The software can run on the same PC connected to the CAM or the part program transfer system.

1. COLLISION THRESHOLD

2. VIBRATION THRESHOLD

A single control unit installed in the electrical cabinet of the machine tool.

TECHNICAL DATA OF THE CONTROL UNIT:

Equipped with 8 PLC outputs from the machine tool.

Requires 3 PLC inputs to the machine tool.

Dimensions approximately 200x100mm

Power supply 24VDC

Mounted on a DIN rail

TECHNICAL DATA OF THE SENSOR:

Compact dimensions (approximately 60x100mm)

Cable length from 10 meters up to a maximum of 50 meters

Quick installation times

Magnetic attachment with neodymium magnets

YOU CAN DECIDE ON WHICH THRESHOLD TO GENERATE THE ALARM OR SIMPLE NOTIFICATION

TECHNICAL DATA OF THE SENSOR:

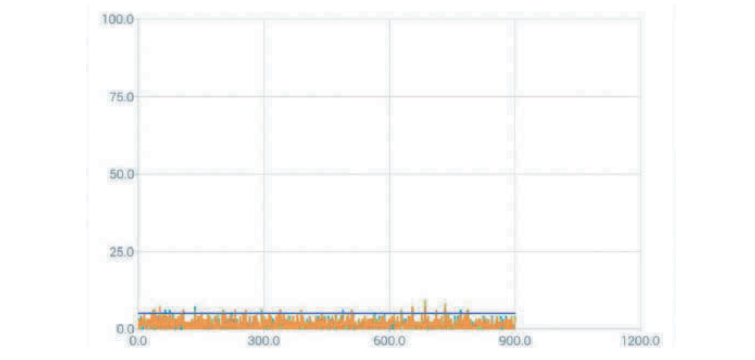

OPTIMAL STATE EXAMPLE

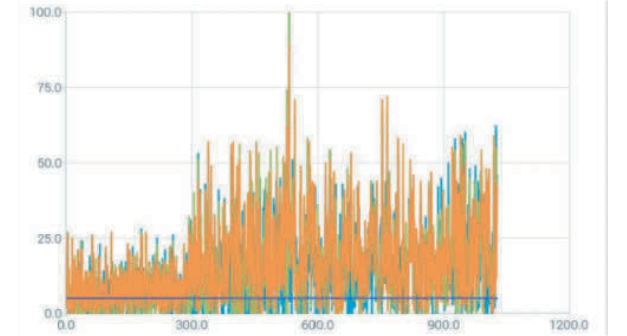

ALARM STATE EXAMPLE

INSTALLABLE ON THE BEST CNC MACHINES

ITHE SYSTEM IS PROVIDED WITH COMPLETE INSTALLATION AND USER TRAINING.

Emmediemme Srl

P.IVA 03998620409

via dell’Orzo, 17 47822 Santarcangelo di Romagna (RN)

Copyright 2024, SeA TECH

di Emmediemme Srl All Rights Reserved.